Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Have you ever asked yourself what makes the small fan on your desk spin? Or how a simple motor in a toy train works? The answer is often a smart little device. It is called a shaded pole induction motor.

This article is for you. It helps you understand how everyday things work. We will explain the shaded pole induction motor in simple parts. You will learn about its simple construction. You will learn how the “shade” on its poles makes it turn. You will also learn what kind of application it is used for. After reading, you will see the great idea behind this small but important motor.

A shaded pole induction motor is a very simple type of single-phase induction motor. Other motors need special parts to get started, but this one does not. It can start all by itself. This makes it a self-starting motor. Because of this, it is perfect for small things that do not cost a lot of money. The secret to how it starts is something special about its poles.

The name tells you a lot about it. It is an “induction motor.” This means it uses a magnetic field to make the rotor turn. The rotor is the part that spins. There is no direct electrical wire connecting them. The most important part is the “shaded pole.” Each pole in the motor has a small section of it covered. This cover, or “shade,” is a copper ring. This simple shade is what makes the whole thing work. The shaded pole induction motor shows a very smart and simple way of making things.

This type of motor is called a shaded pole induction motor because of this special part on its poles. The shade is not a real shadow from light. It is an electrical kind of shadow. It makes the magnetic field late in that part of the pole. This delay is the key to making the motor move. We will look closer at how this simple shade on the poles makes a turning force. The shaded pole induction motor is very interesting.

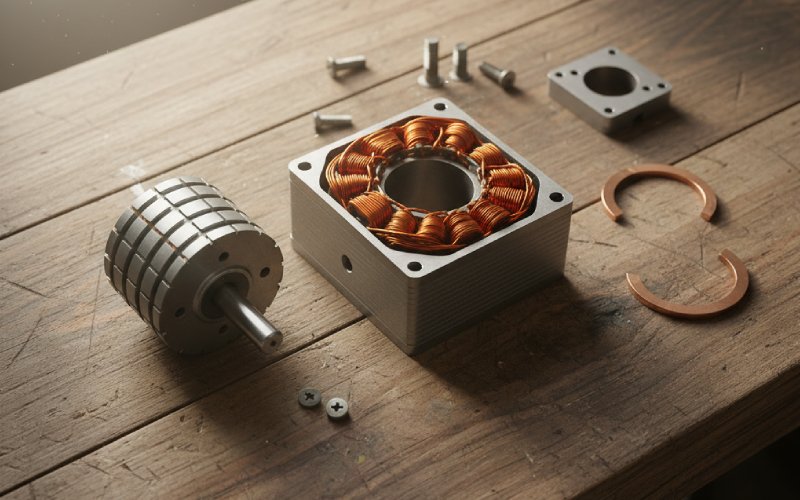

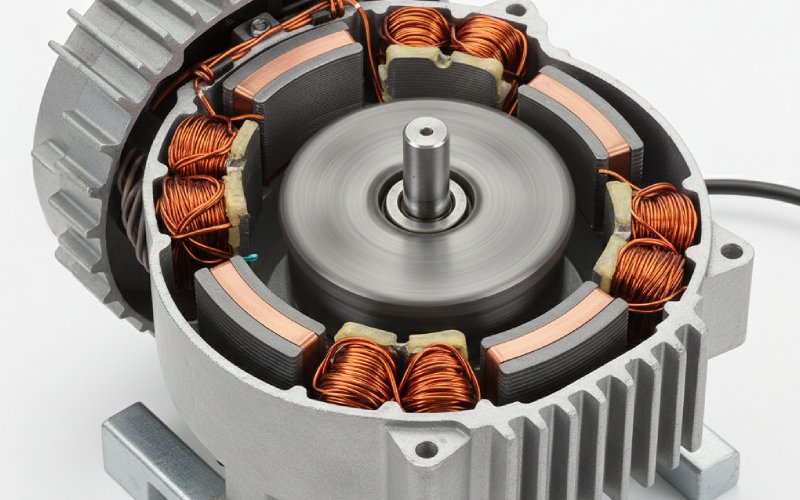

The way a shaded pole induction motor is built is one of its best things. Its construction has very few parts. This makes it cheap to make. It also works for a long time. The main parts are the stator and the rotor. The simple way it is built is why it is used in so many small machines.

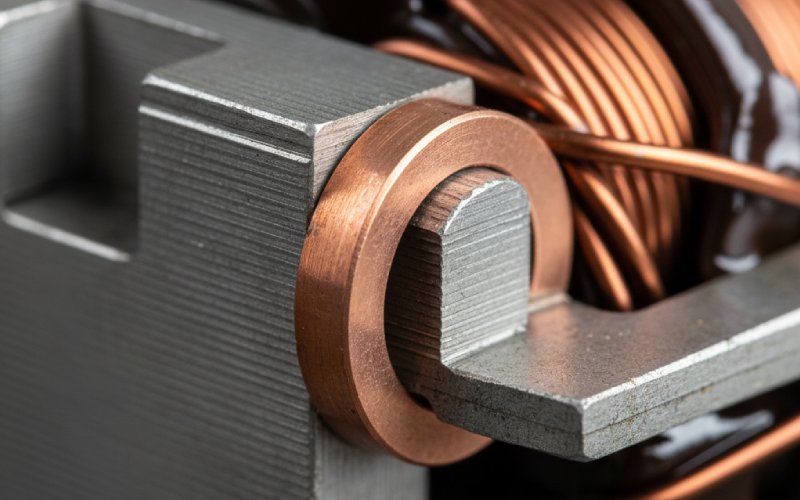

The stator is the part of the motor that does not move. The stator of the shaded pole motor is made from thin sheets of iron pressed together. This is the core. The core has poles that stick out. These are called salient poles. A main coil of wire is wrapped around these poles. This is the winding. When you connect this coil to an AC power supply, it makes a magnetic flux that changes. The most important part of the stator is the “shade.” A slot is cut across a part of each of the poles. A copper ring, also called a shading coil, is put in this slot. This ring gives the shade for the pole.

The rotor is the part that spins. In a shaded pole motor, the rotor is usually a squirrel cage type. This means it is a cylinder made of iron sheets with copper or aluminum bars going through it. These bars are joined by rings at both ends. The rotor does not have any windings or brushes. It is a very simple and strong part. The rotor turns because of the way the magnetic field from the poles works with the current it creates in the rotor bars.

When we say “shade” on the poles, we do not mean a shadow from the sun. The “shade” is a small, single ring of copper wire. It can also be a solid copper ring. This ring is wrapped around a small part of each of the motor’s poles. This part of the pole is called the shaded part. The other part of the pole is the unshaded part.

This shade is a coil of wire that is connected to itself. Because of how electricity and magnets work, when the magnetic flux from the main coil changes, it will create an electrical current in the copper shade. This new current creates its own magnetic flux. This new flux will push against the change in the main flux. The presence of the shading coil creates a second magnetic field. This second field is out of step with the first one.

You can think of it this way. The main winding makes a magnetic field across the whole pole. But the shade pushes back on this field in its own small area. This “push” is not always the same. It makes the magnetic flux in the shaded portion come later than the flux in the unshaded part. So, the shade makes a time delay for the magnetic field on one side of the pole. This little delay is the most important thing. The shade is what makes the motor work. The shade on the poles is the motor’s starting tool.

The special trick of the shaded pole induction motor is how it makes a moving magnetic field with only a single phase of AC power. The shade on the poles is the key. It makes the magnetic flux “move” from one side of the pole to the other. This moving flux acts like a weak spinning magnetic field.

Here is how the moving flux works to start the motor. When the AC current in the main winding goes up, the magnetic flux in the poles also gets stronger. This change will induce a current in the shading coil. The current in the shading coil creates another flux that pushes against the main flux. This means the magnetic flux is stronger in the unshaded part of the pole. It is weaker in the shaded part of the pole.

When the main flux is at its highest point, it stops changing for a moment. At this time, the shade coil does very little. The flux spreads out over all of the poles. Then, as the main flux begins to get weaker, the shade coil makes a current again to push against this change. It tries to keep the flux strong. This makes the flux stronger in the shaded part of the pole. The final result is that the center of the magnetic field moves. It moves from the unshaded part to the shaded part of the pole. This movement happens again and again with every cycle of the AC supply. This makes a weak turning force on the rotor, and this force makes it start to spin.

Let’s look at the full operation of a shaded pole motor during one cycle of the AC power. The way the magnetic flux moves across the poles is what gives the force to make the rotor spin.

This cycle happens over and over. It happens 60 times every second if you have a 60Hz power supply. The magnetic field is always moving across the face of the pole. It moves from the unshaded side to the shaded side. This moving field pulls the bars of the squirrel cage rotor with it. This pulling action makes the rotor spin. This is how the motor can start and keep running.

One of the main things to know about a shaded pole induction motor is that it has a very low starting torque. Starting torque is the turning power a motor has when it first starts up. This weakness is because of the way it is built.

The rotating magnetic field made by the shade on the poles is not a real, smooth spinning field. It is more like a wobbly or moving flux. The time difference, or angle, between the flux in the shaded part and the unshaded part of the poles is small. Because this field is weak and not smooth, the force it puts on the rotor at the start is also very weak.

This means a shaded pole induction motor cannot start if it is connected to a heavy job. It is only suitable for tasks where the work is very light at the beginning. A small fan blade or a small water pump are good examples. As the motor accelerates, the turning power is produced more by the main single-phase induction motor action. But the first push is always soft. The low starting torque is a big downside that you get for its simple design.

You can find the shaded pole induction motor in many small things you use every day. It is a popular choice for any application that needs a small amount of power and does not need a powerful start. This is because it costs little money, is built in a simple way, and works for a long time.

The most common application is in small fans. For example, think about desk fans, fans that pull air out of bathrooms, or the small fans that cool down electronics like projectors or computers. These are all perfect jobs for a shaded pole motor. A fan blade needs very little power to start spinning. Other uses are:

These motors are a type of low power motor. They are not used for big jobs. For example, you would not find them in washing machines or power tools. Those machines need much higher starting torque and better efficiency. But for any small device that just needs to spin, the shaded pole induction motor is often the best pick.

It is very hard to make a shaded pole induction motor much more powerful. The way it is designed is what limits its power and efficiency. The method used to start the motor, with the shade on the poles, wastes a lot of energy.

A lot of energy is turned into heat and is lost. This happens a lot in the shading coil. This loss means the motor has very low efficiency. The efficiency is often between 5% and 35%. The power factor of this motor type is also very low. The power factor tells you how well the motor is using the electrical power it gets. A low power factor means more energy is being wasted.

You can make small changes to the motor. You could use better materials or change the shape of the poles or the shade. But you cannot make a shaded-pole motor into a very strong motor. Its job is to be a simple, low-cost motor for low power needs. If you need more power or better efficiency, you would use a different type of motor, like a capacitor-start motor. The shaded pole motor is best at the job it was made for: simple tasks with low starting power.

Like any tool, the shaded pole induction motor has good things and bad things about it. Its good points are why it is so common. Its bad points limit the jobs it can do.

| Advantages | Disadvantages |

|---|---|

| Simple to Build: Has very few parts. No brushes or special starting parts. | Weak Starting Power: Cannot start with a heavy job. |

| Low Cost: The simple design and parts make it very cheap to make. | Wastes a lot of energy: A lot of electrical power turns into heat. |

| Works for a Long Time: It has no brushes that can wear out, so it can last a long time. | Low Power Factor: Does not use power from the wall socket very well. |

| Starts by Itself: It does not need a special part to get it started. | Low Power: It is only good for small jobs that do not need much power. |

| Strong: The squirrel cage rotor is very tough and hard to break. | Speed is Hard to Change: Its speed is mostly set by the power from the wall. |

You get one good thing, but you also get a bad thing. You get a very simple design and a low price. But in return, you get a motor that does not perform very well. For a small fan, this is a good deal. For other jobs, the poor efficiency and low starting torque are big problems.

The number of poles in any AC motor changes its speed. This is also true for a shaded pole induction motor. The spinning speed of the magnetic field is called the synchronous speed. This speed is decided by two things: the frequency of the AC power and the number of poles.

The link is simple. The more poles you have, the slower the motor will be. The speed of the motor is inversely related to the number of poles. For example, a two-pole motor will run faster than a four-pole motor, even if they use the same 60Hz power. The real running speed will be a little bit slower than the synchronous speed.

Most shaded pole induction motors have a two-pole or four-pole design. Using more poles can sometimes make the motor run more smoothly. But it also makes the construction a little harder. The choice of how many poles to use depends on the speed needed for the job. The number of poles is a key part of how the motor is designed. The poles and the shade on the poles are what make the motor work the way it does.