Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

The secret behind every electric vehicle (EV), from a high-speed train to your family car, is the electric traction motor. This article will explain what a traction motor is, how it works, and why it’s so important. You’ll learn about the different motor types and see why this amazing machine is changing how we travel. This is worth reading because understanding the traction motor helps you understand the future of transportation.

People see an electric vehicle and wonder what makes it move. The simple answer is a traction motor. A traction motor is an electric motor that is used for propelling the vehicle. Think of it as the engine for an electric car or train. Its only job is to turn the wheels. This special electric motor is designed to create turning force, which we call torque.

The motor is an electric motor that turns electrical power into movement. It takes electrical energy into mechanical energy. This energy is then sent to the wheels, usually through an axle. So, when you press the pedal in an EV, you are telling the traction motor to start turning. These motors are used to drive the vehicle forward or backward. It’s the heart of any machine that uses electric traction.

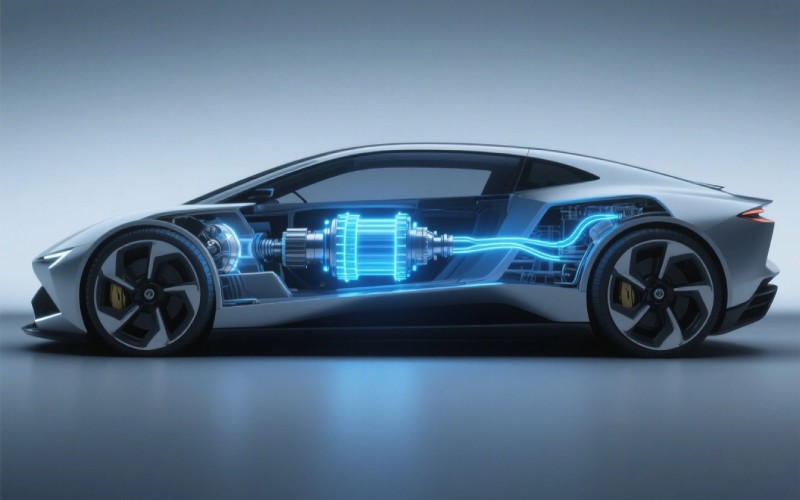

To understand a traction motor, let’s look inside. Imagine it as two main parts. There is a stationary part on the outside called the stator. Inside the stator, there is a spinning part called the rotor. The stator has coils of wire called a winding. When an electric current is sent through this winding, it creates a magnetic field.

This magnetic field makes the rotor want to spin to line up with it. To keep it spinning, the system creates a rotating magnetic field. This constant spinning of the rotor is what creates the torque needed to move the vehicle. The whole process is about converting electrical energy into mechanical motion. This basic idea of a stator and rotor is used in almost every traction motor, from a simple one to a very advanced one. The motor operation is smooth and quiet.

Traction motors are used in many big machines. The biggest user is the railway industry. Every modern locomotive and all electric trains use a powerful traction motor to pull heavy loads. In fact, railway transportation has used this technology for over a hundred years.

You can also find them in things like trams, trolleys, and even huge mining trucks. These are not like small industrial motors you might see in a factory. A traction motor is built for tough jobs. It has to handle bumps, dirt, and all kinds of weather. The traction motor in a locomotive is a great example of a machine built for power and long life. The next time you see a train, remember there is a strong traction motor doing all the work.

This is a great question. No, not all traction motors in EVs are the same. Just like gas engines are different, there are many kinds of traction motors. The motor design depends on the type of electric vehicle. A small city EV will have a different motor than a large electric truck or a sports car. The power rating of the traction motor will be very different.

Engineers choose a traction motor based on many things. They look at cost, size, weight, and high efficiency. Good motor performance is key. Some car makers might choose an induction motor, while others might use one with a permanent magnet. The goal is always to get the best performance for that specific EV. The rating of the traction system is matched to the vehicle’s needs. This is why there is so much new research on the ev traction motor.

Let’s talk about the main motor types. For a long time, the DC motor was very common. The old brushed DC motors were simple but needed a lot of care. Today, most vehicles use an AC motor. The two most popular kinds are the induction motor and the synchronous motor. The induction motor, also called an asynchronous motor, is strong and reliable.

The other popular type is the permanent magnet synchronous motor, or PMSM. These motors use strong magnets and are known for their high efficiency. There are also other types, like reluctance motors. A switched reluctance motor is very strong but can be noisy. When you look at modern electric cars, you will often find an induction motor or a PMSM type of traction motor. These motors and synchronous designs are leading the way.

Torque is the most important thing for a traction motor. Torque is the twisting force that makes the wheels turn. When you are at a stoplight and it turns green, you want your car to go right away. That instant “get up and go” feeling comes from high torque at low speed. A traction motor is great at this. It can generate its full torque from a complete stop.

A gas engine has to rev up to make its best power, but a traction motor does not. This is why electric cars feel so quick. The traction motor must be able to produce a lot of torque to get a heavy vehicle moving. This force is sent through the axle to the wheels. Whether it’s a small car or a giant locomotive, the ability to make strong torque is what makes the traction motor so special. The motor must be able to handle these high loads. A locomotive needs huge amounts of torque to start pulling a long train from a standstill.

A high-speed train is an amazing piece of engineering. To reach such high speeds, it needs a very special traction motor system. These trains run on AC power from overhead lines. This high voltage power goes through a traction transformer on the locomotive to get the right power level for the motors. The motors are used to drive each axle or a set of axles.

The control system for a high-speed train is very advanced. It has to manage the power going to each traction motor perfectly. This ensures a smooth ride and safe operation. The railway tracks and the power system are all designed to work together. The traction motor in a modern locomotive is a great example of high power technology. This is a key part of modern traction electric systems.

The big difference is how they are built and controlled. A DC motor was the early choice for electric traction. A simple brushed DC motor uses brushes to send power to the spinning part, called the armature. These brushes wear out and need to be replaced. Modern systems use AC motors, like the AC induction motor. These motors do not have brushes, so they last longer and need less work.

An AC traction system allows for very precise control of the motor’s speed. The motor is controlled by changing the frequency of the AC power sent to it. This is done by advanced electronics called motor controllers. While a DC motor is simpler in design, an AC traction motor offers better performance and reliability. The induction principle in an ac induction motor makes it very robust.

A standard electric vehicle only has a traction motor. But hybrid electric vehicles have both a gas engine and an electric motor. In a hybrid, the traction motor helps the gas engine. This saves fuel, especially in city driving. The EV part of the car can handle low-speed driving, and the gas engine kicks in for more power or higher speeds.

Some hybrids have an induction motor, while others use different types. Traction motors provide the instant torque that makes hybrids feel quick from a stop. These motors also work as generators. When you brake, the traction motor helps slow the car down and uses that energy to recharge the battery. Often there are two motors, one acting as a generator and the other as the main drive motor. This makes the whole electric vehicle system more efficient.

I believe the future of the traction motor is very bright. New motor technologies are making them even better. The biggest trend is the move toward motors with even high efficiency. The permanent magnet synchronous motor, or PMSM, is a great example. These motors use a permanent magnet made from rare-earth materials to create a strong magnetic field. This makes the pmsm very efficient and powerful for its size.

Engineers are also working on new designs that don’t need rare-earth magnets. The goal is to make the traction motor cheaper and better for the planet. We will also see better control capabilities. This means the control system will manage the electric energy even more smartly. As the world moves to an electric vehicle future, the humble traction motor will become more important than ever. The efficiency of traction motors will continue to improve.