Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

A transformer is a very important part of the system. Knowing its lifespan is key to taking care of any electrical setup. A transformer is a big purchase, and you want it to last as long as possible. A transformer usually lasts for about 20 to 30 years. But this can change. Some transformers can work for a much longer time, even 40 years or more, if you take good care of them.

This article is for anyone who wants to know what affects a transformer’s life. I will also explain how to make it last longer. I will share my own experiences and what I have learned. We will look at many things that can shorten or lengthen the working life of a transformer. We will cover everything from how well it was made to how you use it day to day. My hope is to give you helpful tips to protect your purchase and make sure your power supply is steady.

From what I’ve seen, there is no single answer for how long a power transformer will work. Most of the time, you can expect a power transformer to have a life of 25 to 30 years. Distribution transformers are also very common. They often last for about 20 to 30 years on average. But this is just an average number. I have seen a power transformer stop working much sooner. I have also seen some that keep going long past this time. The real working life of a transformer depends on many different things.

One big factor is how the transformer is used. A transformer that is always working at its highest power level will have a shorter life. A transformer that works with a smaller amount of power will last longer. The place where the transformer is kept also makes a big difference. A transformer in a hot and dusty area will not last as long as one in a clean and cool spot. The quality of how it was made in the beginning is also very important. A well-built transformer from a good company is a better choice for the long run. So, we can talk about an average lifespan, but how long a certain transformer lasts can be very different.

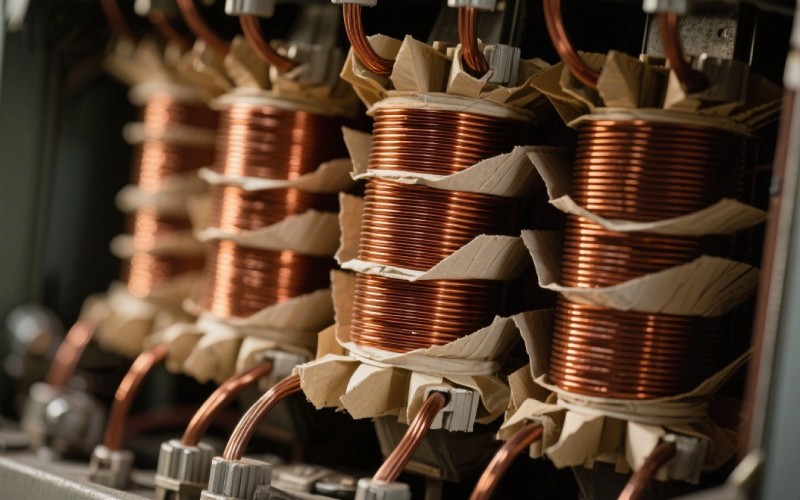

When we talk about what decides the life of a transformer, the insulation is the most important thing to me. The solid insulation inside a transformer is usually made of a special paper. This insulation is a very important factor. The main job of this paper insulation is to stop electricity from jumping between the winding coils. Over the years, this insulation starts to wear out. We call this process aging. The health of the insulation has a direct effect on how the transformer works and, in the end, on its life. When insulation stops working, it is a very common reason for a transformer to fail.

The aging of the insulation is a process that cannot be undone. Heat, water, and air all work together to make the paper insulation break down. As the insulation gets older, it becomes weak and can break easily. This makes the winding more likely to get hurt by electrical and physical stress. You can think of it like an old rubber band. It gets stiff and can break very easily. When the insulation cannot do its job anymore, it can cause the whole transformer to have a major failure. This is why I always say it is so important to check the condition of the insulation.

I need to say this very clearly: heat is the biggest enemy of a transformer. The temperature a transformer works at is one of the biggest things that affects its life. Every transformer makes heat when it is working normally. This happens because of small electrical losses in the winding and the core. The trouble begins when this temperature gets too high. High working temperatures make the aging of the transformer’s insulation happen much faster. This includes both the solid paper insulation and the special oil that insulates.

There is a rule that is well known. For about every 8 to 10 degrees Celsius that the working temperature goes up, the life of the insulation is cut in half. This shows how much temperature affects the transformer’s insulation. The hottest place inside the winding is called the hot spot temperature. This is what we really need to watch. Working at high temperatures all the time leads to the insulation breaking down at a faster rate. That is why it is so important to have a good cooling system and to watch the transformer’s temperature. If you can keep the transformer cool, you can make its life much longer.

The amount of work, or load, a transformer does has a direct effect on its temperature. As we just talked about, temperature is a very big factor in a transformer’s life. When you make a transformer do more work than it was built for, we call it overloading. If you overload it all the time, the transformer will get too hot. This extra heat makes the insulation break down faster. This leads to a shorter transformer life. I have seen many transformers fail too early just because the need for power grew over time. The transformer was never changed to a bigger one to handle the higher load.

It is not just about overloading all the time. Quick, big changes in the load can also create heat stress on the transformer’s winding and insulation. Over time, this can make the insulation weaker and raise the chance of a failure. A key way to make your transformer last longer is to manage its load. This can mean checking the power usage and, if you need to, moving some of the electrical work around. This helps stop any one transformer from being overloaded all the time. Keeping the transformer working within the power range it was designed for is very important for a long and good working life.

I have seen with my own eyes how the area around a transformer can change it. Transformers are often put outdoors. There, they have to deal with many different kinds of weather and conditions. These things can have a big effect on how they age.

Here are some of the main things in the environment to think about:

| Thing in the Environment | Effect on the Transformer |

|---|---|

| High Outside Temperatures | Hot weather outside makes it harder for the transformer to cool off. This leads to higher temperatures inside and faster aging of the insulation. |

| Wetness and Water | A lot of wetness in the air can let water get inside the transformer. Water is very bad for the insulation and the oil. It makes them less able to insulate. |

| Dust and Dirt | Dust and other dirt can pile up on the transformer’s cooling parts. This makes the cooling system work less well. This can make the transformer run hotter. |

It is important to protect a transformer from these tough outside conditions. You can do this by using special covers or making sure there is enough airflow to help the unit stay cool. Cleaning it often to get rid of dust and dirt is also a simple but good way to help the cooling system do its job.

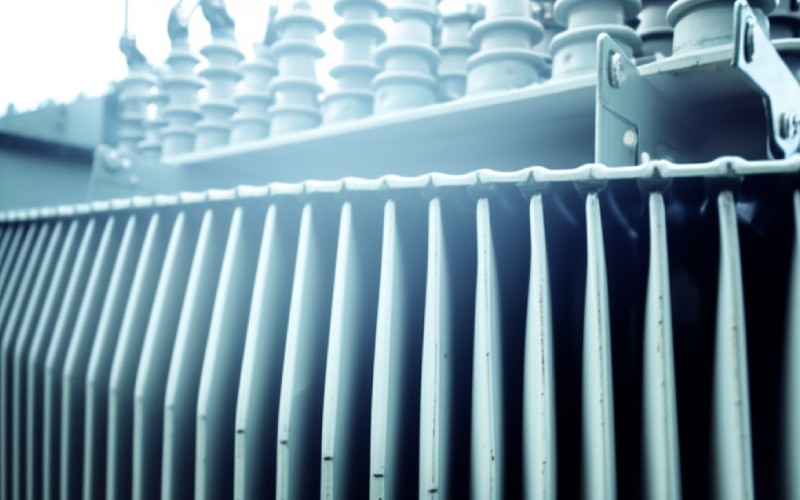

For oil-filled transformers, the oil does two very important things. It works as an insulator, and it helps to keep the transformer cool. The quality of this oil is very important for the health and life of the transformer. Over time, the oil can get dirty with water, air, and other small bits. This dirt makes the oil break down. When the oil breaks down, it cannot insulate or cool as well as it should.

Bad oil can also turn acidic. This can hurt the solid paper insulation and other parts inside the transformer. This is why checking the transformer oil on a regular basis is a normal part of taking care of it. We check for things like how much water is in it, its dielectric strength (how well it can insulate), and if it is acidic. If the oil is in bad shape, we can clean it or change it. This helps protect the transformer and make its life longer. Using high-quality oil from the beginning and keeping it clean and dry is a very smart choice.

Yes, it does. The life of a transformer begins when it is being planned and when it is being built in the factory. The quality of the plan and the parts used to build it have a big effect on how long a transformer will last. A transformer made with high-quality parts, like a good steel core and copper windings, will probably have a longer life. A transformer made with cheaper parts will not last as long. Being careful and exact during the building process is also very important to make a strong and lasting unit.

A good company will have very strict checks for quality. This is to make sure that every transformer they build is made to a high standard. This might mean it costs more at first. But from what I have seen, it is worth it later on because the transformer has a longer life and fewer issues. When you are buying a new transformer, it is a good idea to look into the company’s name and the quality of their items. A strong start from a quality company can help the transformer handle the stress of working over its whole life.

The good news is that you can do many things to make your transformer’s life longer. It is all about taking action early and taking good care of your equipment. Here are some of the best ways I have seen work over the years:

By doing these things, you can control the things that cause aging. You can greatly raise the chances of your transformer having a long and problem-free life.

As a transformer gets older, it will begin to show signs that it is wearing out. If you can see these signs early, it can help you plan to get a new one before it suddenly stops working. Here are some common clues of an aging transformer to look for:

If you see any of these signs, it is a good idea to have a trained person check the transformer to find out what the problem is.

Choosing when to get a new transformer is a big choice. You have to think about the risk of it failing versus the cost of a new one. A transformer failure can be a very big problem. It can lead to no power and costly fixes. After a transformer has been working for 25 to 30 years, the chance of it failing from old age starts to go up a lot.

The choice to get a new transformer is often made based on many things together. These include its age, its condition (from checks and tests), how much it has been used, and how important it is for your daily work. If a transformer is showing many signs of getting old, and especially if it has had problems before, it is probably time to start planning to get a new one. It is a big purchase, but getting a new, better transformer to replace an old one you cannot count on can save you money and trouble later on.