Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Do you help make or design electric motors? If you do, you know that a strong motor core that works well is very important. This core, which is called a stator or rotor, is made from a stack of thin metal sheets. The old way to hold this stack together was to weld it. But there is a much better way: the interlocked lamination. This article will show you how a stack made with an interlocked lamination works. You will learn why this way is cheaper, faster, and better for how well your motor works. Keep reading to learn the easy secrets for building a really good motor stack.

Let’s begin with the simple parts. A lamination is a very thin piece of steel. You can think of it like one page in a thick book. Inside a motor, you do not use a solid piece of steel for the core. Instead, you use a stack of these very thin sheets. Every lamination is covered with a thin layer that stops electricity. This is a very important detail. This special coating stops electricity from moving from one sheet to another in the lamination stack.

Why do we do all of this? It is all about not wasting energy. A motor that is spinning makes a magnetic field. If the core were solid, this field would make electric currents that spin around, like small whirlpools. These currents waste energy by making heat. By using many laminations (a plurality of laminations), we stop these currents. Each single lamination is too thin for a big current to get started. This easy trick helps the motor work better and use less power. One lamination is the main part used to build a strong motor stator or rotor.

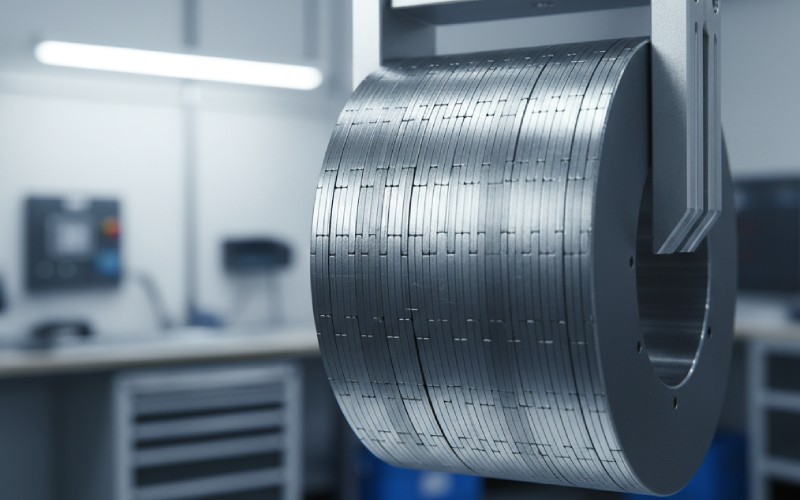

Now you know what a lamination is. So how do they make a core? You take many laminations and press them together. This makes a solid core, which is called a lamination stack. This stack can be for a stator (the part of the motor that does not move) or a rotor (the part that spins). The stator stack has a large hole in its center for the rotor. It also has one slot or many slots on the inside. The copper winding goes into this slot. The winding is the wire that electricity moves through.

When electricity goes through the winding in every slot, the lamination stack turns into a strong magnet. This is the thing that makes the rotor spin. For this to work in the best way, the laminations in the stack must be held together in a very tight way. They cannot be loose. The way you hold the stack of laminations together changes how much the motor costs, how strong it is, and how well it works. The main goal is to make a solid stator core from a simple lamination. This core must lead the magnetic field in just the right way through the electric circuit.

So, what is the best way to hold the stack together? You could use a weld, some glue, or bolts. But a smarter way is to use an interlock. An interlocked lamination is a special kind of lamination. It is made to lock together with the lamination right next to it. It does this without any extra parts. Think about two LEGO bricks clicking together. That is the main idea of an interlock. Every interlocked lamination has little bumps and dents that fit them.

These shapes are made during the manufacturing process. A machine named a punch press cuts out the lamination shape from a large roll of steel. That same machine can also make the interlock shapes. A very common kind is called an interlock tab. This is a tiny piece of metal that is pushed out from the flat side of one lamination. This tab fits just right into a little hole or slot on the lamination next to it. When you stack them, the tab from one lamination locks into the slot of the one under it. This makes a very strong connection.

The magic that makes the interlock happens very, very quickly. It is a smart way to use force to bend the metal. During the manufacturing process, a special tool is used to punch the lamination. Let’s name a certain lamination in our example lamination 20. When the machine makes lamination 20, a tool comes down and makes a small punch on its surface. This does not make a hole that goes all the way through. Instead, it makes a small bend in one spot. This bend is a deformation.

This deformation makes a shape, like a small bump or an interlock tab. For this interlock to work, this small deformation must stick out from the bottom of lamination 20. At the same time, the punch can make a matching dent on the top side of the next lower lamination in the stack. So, when lamination 20 is put on top, its bump locks into the dent of the lamination below it. The important thing is that the deformation is controlled. It needs to be big enough to make a strong interlock but small enough so it does not hurt the lamination’s magnetic properties. The punch press is a very important part of the apparatus and method for manufacturing this part.

Not all interlock shapes are the same. Engineers have come up with many smart ways to make an interlocked lamination connect with the one next to it. The kind of interlock you choose depends on the motor’s size, how thick the lamination is, and how much it costs to manufacture it. Let’s look at a few common kinds.

For many years, the usual way to assemble a lamination stack was to weld the outside. A weld is strong, but it makes things go wrong for a motor. The very strong heat from the weld hurts the special coating on each lamination. It basically melts the edges of the stack of laminations into one piece. This makes a path for the currents that waste energy, which we talked about before.

When you weld a stack, you make a short circuit on the outside of the stator. This harms the magnetic properties and makes the motor use more power. An interlocked lamination does not have this problem at all. Because there is no welding, the coating on each lamination is not harmed. The interlock makes a strong connection without using heat. This leads to a motor that works better and wastes less energy. A view of a stack made with an interlock looks much neater.

Here is a simple table to compare the two ways:

| Feature | Interlocked Lamination Stack | Welded Lamination Stack |

|---|---|---|

| How It Connects | Mechanical interlock | Heat from a weld |

| Wasted Energy | Very Low | High because of a short circuit |

| Magnetic Properties | Very Good | Harmed by heat |

| Making Cost | Lower (one step) | Higher (extra weld step) |

| Stack Strength | Good to Very Good | Very Good |

The great thing about the interlocked lamination is how easy it is to assemble. The manufacturing method is often done all in one step. The laminations are stacked and locked together right there in the stamping press. Think of a machine that uses a punch to cut a lamination from a coil of steel. Let’s call this lamination 20. This lamination 20 is then right away pushed down onto the stack that is being built under it.

The power of the press pushes the interlock tab of lamination 20 into the dent of the lamination that is already in the stack. The lamination positioned on top locks with the one below. This happens again and again, hundreds of times every minute. Each new lamination is cut and right away added to the growing lamination stack. This goes on until the stack is the right height. After that, the finished stator or rotor core is pushed out of the machine. This apparatus and method for manufacturing a stack is very fast and does not waste time. This method for manufacturing said stack is much quicker than adding a separate weld.

The interlocked lamination system is great, but the manufacturing process must be very exact. A tiny mistake can lead to big problems. One large problem is when small mistakes add up. This is called an accumulation of errors. If each interlock is off by just a little bit, these tiny mistakes can add up over a tall stack. This can make the lamination stack be crooked or twisted. The uppermost lamination might not line up with the bottom lamination.

Another problem is when the metal is bent the wrong way. This is an incorrect deformation. If the punch hits too hard, it can cause too much deformation and hurt the lamination. This can harm its magnetic properties. If the punch does not hit hard enough, the interlock will be weak, and the stack of laminations could come apart. The tool used to punch the interlock must be kept in perfect shape. The goal of a good manufacturing method is to keep the bend in one small area, to localize the deformation only where the interlock is. This protects the rest of the lamination.

The main job of a stator or rotor core is to show a magnetic field where to go. If you change the steel in any way, it can change its magnetic properties. As we found out, a weld is very bad because it makes a short circuit between laminations. An interlock is much better, but it is not completely perfect. The deformation made by the punch does put some stress on the steel. This stress can change the magnetic properties a little bit in that small spot.

But, engineers work very hard to make this problem as small as possible. They design the interlock to be as small as it can be while still being strong. They put the interlock shapes in parts of the lamination where the magnetic field is not as important. For example, they are often put far from the teeth where the winding is. The small effect of an interlock is a small trade-off for a big improvement from removing the bad weld. A well-made interlock helps create a lamination stack that makes a motor that works very well.

The world of electric motors is always getting better. Companies that make cars, home appliances, and factory tools all want a motor that is smaller, costs less, and is more powerful. This means the technology for the lamination and the stator needs to improve. We are seeing new manufacturing laminated assemblies having ridges that are even more complex. These designs make an even stronger interlock with less deformation.

New kinds of materials are also being used for the lamination. Thinner steels that have better magnetic properties are helping to build a motor that uses less power. The apparatus and method for manufacturing these parts is also getting better. Very fast presses and smarter tools can manufacture a lamination stack with great care so everything is exact. The simple interlocked lamination will keep being a very important part of building the future of electric motors, armatures, and generators. From a simple punch on a thin sheet of steel, a powerful motor is born.