Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

This article will tell you the story of Silicon Steel. You will learn why this specific kind of silicon steel is the number one choice for making the heart of every transformer.

Let’s start with the basics. A transformer has two main parts: a primary winding and a secondary winding. These are just coils of wire. When you send an electric current through the first coil, it creates a magnetic field. The job of the transformer core is to guide that magnetic field over to the second coil. This process is based on the principle of electromagnetic induction.

The core acts like a road for the magnetic energy, which we call magnetic flux. We want as much of this flux as possible to travel from the primary winding to the secondary winding. If the road is bumpy or has a lot of holes, we lose energy along the way. That’s why the material we use for the iron core is so important. A good core material makes sure the journey is smooth and efficient. The iron core is usually called the magnetic core because its main job is to carry this magnetic energy.

You might be wondering, “Why not just use a simple block of iron?” After all, steel itself is a magnetic material and iron is cheap. The problem is that a regular iron core wastes a lot of energy. This wasted energy is called iron loss or core loss. This loss in the iron core turns into heat, which is bad for the transformer and wastes electricity.

This iron loss is caused by two main problems that happen inside the core material. Imagine the magnetic flux flowing through the core. Because the transformer always works with an alternating current (ac), the magnetic field is constantly flipping back and forth. This constant change causes energy losses. These losses mean you get less power out of the transformer than you put in. We need a special magnetic material to fight this power loss.

This is where silicon steel comes to the rescue. Silicon steel is an amazing magnetic material that is mainly used for making transformer cores. So, what are its secrets? First, it has very high permeability. Think of permeability as how easily a material can be magnetized. Silicon steel lets the magnetic flux flow through it very easily, like water through a wide, smooth pipe.

This property of high magnetic permeability is one of the biggest reasons silicon steel is used. It means the core can create a strong magnetic path with very little effort. The key ingredient, of course, is silicon. The silicon content in the steel changes its magnetic properties. We use a specific kind of silicon steel with just the right amount to get these great results. This excellent magnetic permeability is a huge advantage for a transformer made of silicon steel.

One of the two big energy wasters is called hysteresis. Imagine you have a lot of tiny magnets, called magnetic domains, inside the iron core. When the magnetic field is on, they all line up. When the field flips, they all have to flip around. This takes energy. Hysteresis is like friction for these tiny magnets. A material with high hysteresis is hard to magnetize and then hard to be demagnetized.

This constant flipping creates hysteresis loss. We need a material with low coercivity, which means its tiny magnets can flip back and forth easily. Silicon steel is designed to have very low hysteresis. The process of making silicon steel helps the magnetic domains move freely. This reduces the friction and lowers the amount of energy wasted as heat. This special property is crucial for making an efficient transformer. The special way they make silicon steel helps reduce this loss is caused by two factors.

The second big energy waster is called the eddy current. When the changing magnetic flux passes through the iron core, it creates small, swirling pools of electrical current inside the metal itself. This is because of induction. These little whirlpools are called eddy currents. They don’t do any useful work. Instead, they just heat up the core.

This heating is called eddy current loss. This loss is caused by two reasons, but eddy currents are a big one. Think of it as the current taking a wrong turn and getting lost inside the core, creating heat instead of helping transfer power. The power loss in the iron core is a serious problem because it wastes electricity and can cause the transformer to overheat. The iron core of the transformer can get very hot if we don’t control these currents.

So how do we stop these little whirlpools of current? This is another place where silicon steel shines. The trick is to make it harder for the eddy current to flow. We do this by increasing the metal’s electrical resistance, also known as its resistivity.

The addition of silicon to the iron does exactly that. The silicon atoms get in the way and make it much harder for the swirling currents to move around. Higher resistance leads to lower eddy current flow, which means less energy is wasted as heat. This is a simple but very clever solution. Using silicon steel is a great way to reduce eddy current problems and make the transformer much more efficient. It is one of the key reasons why steel is used.

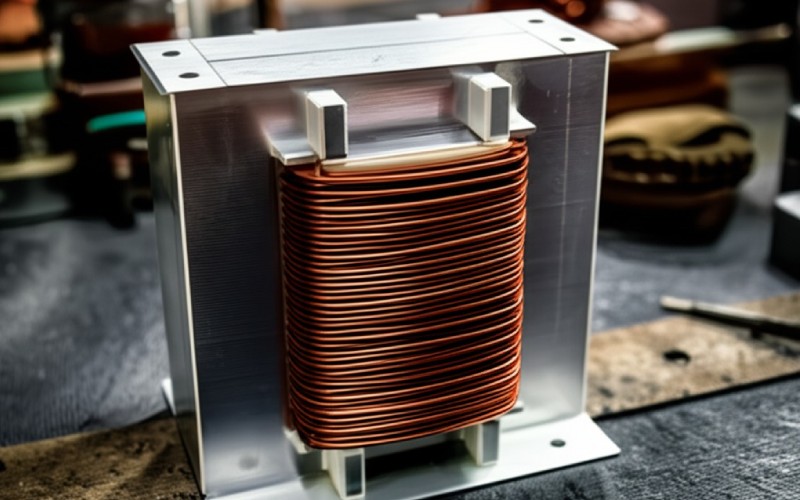

If you ever look closely at a transformer core, you’ll see it’s not a solid block of metal. It’s made of many thin layers of silicon steel sheet stacked together. This is called lamination. This is the second part of the plan to defeat the eddy current.

By slicing the iron core into thin sheets, we break up the path for the eddy currents. A lamination acts like a barrier. The eddy current can’t flow across the thin insulating layer between the sheets. This forces the whirlpools to be very, very small. Small whirlpools mean much lower eddy current loss. Using a solid core in that way will greatly increase the losses. The rule is that the narrower the spliced sheets are, the better the effect. That’s why a single silicon steel sheet is often just 0.35mm thick. This structure reduces the eddy current very effectively.

Not all silicon steel is the same. There are two main types: hot-rolled silicon and cold-rolled steel. The names describe how the steel is made. Hot-rolled silicon steel is processed at a very high temperature. It’s a good material, but there’s an even better one.

Cold-rolled silicon steel sheets are processed at room temperature. This process lines up the grains of the steel in a very specific direction. This makes it even easier for the magnetic flux to flow, giving it a large magnetic induction intensity. This special electrical steel has even better magnetic properties and lower energy loss. For high-performance power transformers, the material used is almost always cold-rolled silicon steel. This advanced material for transformer cores is a big part of modern electrical systems.

Creating high-quality silicon steel is a careful science. To make silicon steel perfect for a transformer, manufacturers start with low carbon steel. Then, they add the right amount of silicon. A high silicon content increases resistivity, which is great for stopping eddy currents.

After rolling the steel into thin sheets, they have to anneal it. To anneal means to heat the steel and then cool it down slowly. This process removes stress from the metal and helps form the perfect grain structure for amazing magnetic performance. This careful process is why silicon steel has a low thermal expansion coefficient. It also ensures the material has a strong magnetic response when placed in an energized coil.

So, let’s bring it all together. Using silicon steel is the best choice for a transformer core because it is a champion at reducing energy loss. A transformer made of silicon steel has low core loss because it solves the two biggest problems: hysteresis and eddy current losses. Because of all the above-mentioned favorable factors, it’s the clear winner.

Its high magnetic permeability creates a smooth road for the magnetic flux. The silicon inside raises the resistance to stop wasteful eddy currents. The lamination design breaks up the eddy currents even more. This leads to amazing transformer performance. It means we waste less electricity, which saves money and is better for our planet. It also reduces temperature rise, which helps the transformer last longer. This is why silicon steel is so important for all kinds of devices used in electric power systems.