Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

I have worked with electric motors for a very long time. I have seen big motors, small motors, and motors that do very special tasks. One of the most interesting motors I have seen is the wound rotor induction motor. It is a very hard worker. If you ever asked yourself how a big crane can lift heavy things so smoothly, you might be seeing what this special motor can do.

This article is for you if you want to learn about this strong type of motor. We will look at what a wound rotor motor is and how it works. We will also see why it is so different from the common squirrel cage motor. I will explain it in simple words. When you finish reading, you will know exactly why this motor is the right pick for some of the hardest jobs.

Let’s begin with the simple facts. A wound rotor motor is a special type of induction motor. You may also hear it called a slip ring motor. Just like other electric motors, it uses magnets and electricity to make things move. The main task of any motor is to change electrical power into moving power. This motor does this task very well, especially when the job is tough.

The name “wound rotor” tells you the most important thing about it. The rotor is the part of the motor that spins. On this motor, the rotor has coils of wire wrapped around it. These wires are called windings. These are not just plain metal bars. They are insulated windings. They are a lot like the windings in the part of the motor that does not move, called the stator.

This special winding on the rotor is the key to its power. It is a type of induction motor where the rotor windings are linked to things outside the motor. This link lets us change the way the motor works while it is running. This outside control is what makes the wound rotor induction motor such a unique and strong machine. We will see how this one simple part can make a very big difference.

When I talk about motors, most people think about the normal squirrel cage induction motor. It is the most used type of AC motor in the world. It is simple, it does not cost much, and you can count on it. The name “squirrel cage” comes from its rotor. The rotor looks like a cage for a small animal. It is made of a set of metal bars that are joined at the ends.

The wound rotor induction motor is not the same. It does not have a simple squirrel cage rotor. Instead, its rotor is more detailed and has windings. When you compare it to squirrel cage motors, this is a very important difference. The simple squirrel cage motor is a “set it and forget it” type of machine. When you turn it on, its speed and turning force are pretty much set. It does one task at one speed very well.

The wound rotor motor, on the other hand, is able to change. We can connect to its rotor windings. This means we can change how it performs at any time. This makes the motor more detailed and it often costs more money. But for some jobs, being able to change is just what is needed. A squirrel-cage motor is like a car with just one gear. A wound rotor motor is like a car where you can change all the gears.

| Feature | Wound Rotor Motor | Squirrel Cage Motor |

|---|---|---|

| Rotor Type | Coils of wire (windings) | Solid metal bars |

| Starting Torque | Very high and can be changed | Medium to high, but is set |

| Starting Current | Low and can be controlled | Very high |

| Speed Control | Good, can be changed | Poor, runs at almost one speed |

| Cost | Costs more | Costs less |

| Upkeep | Needs more (brushes and slip rings) | Needs very little |

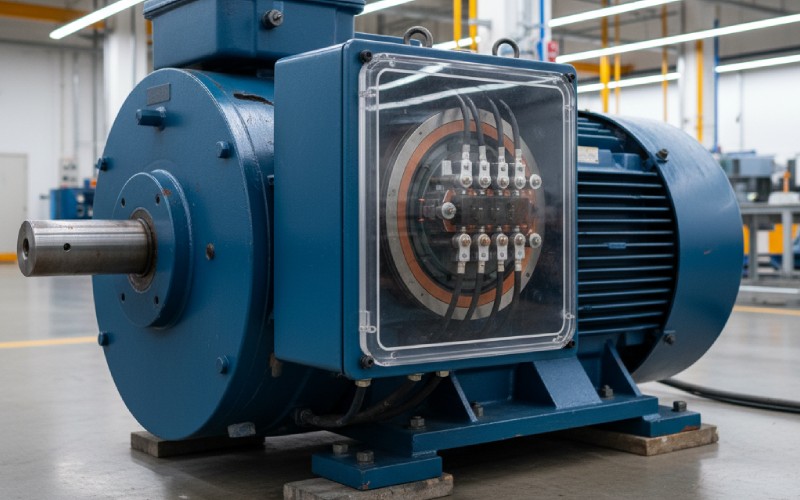

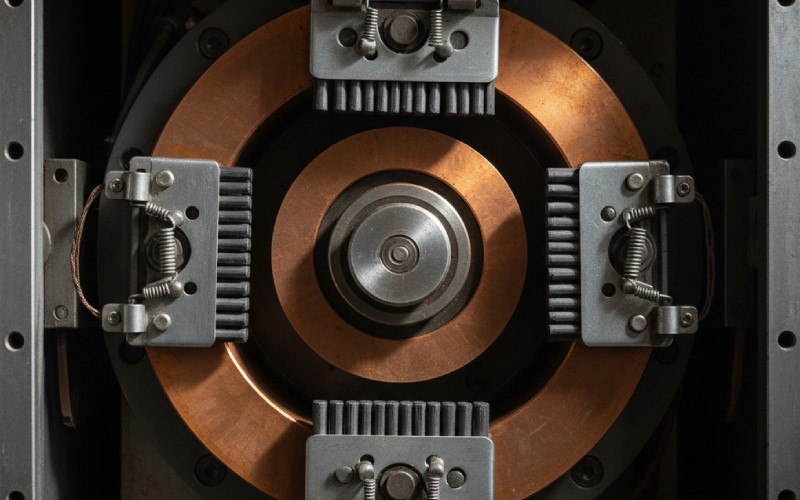

So, how do we make a connection to the spinning rotor? That is where slip rings and brushes are used. Think about trying to connect wires to something spinning a thousand times a minute. It would be a big, tangled mess! The slip ring is a smart answer to this problem. A slip ring is a metal ring. It is on the motor’s spinning rod, but electricity cannot pass between the ring and the rod.

The rotor windings are connected to these slip rings. When the rotor spins, the rings spin with it. Some carbon blocks that do not move, called brushes, touch the rings. The electricity moves from the spinning rotor windings, through the slip rings, and into the brushes. Then it goes out to a control box on the outside. This lets us add parts to the rotor circuit.

This is the key to how a wound rotor induction motor works. Without brushes and slip rings, we could not connect to the rotor. We would have no way to change the resistance in the rotor circuit. This part sounds simple, but it is what makes this type of motor so special. It gives us a lot of control over its power. This motor is a great example of smart design.

The best part about this motor is that you can control its speed. The speed control is connected to those slip rings we just talked about. We can connect a set of resistors on the outside to the rotor circuit through the brushes. This lets us change how the motor works. A resistor is a part that makes it harder for electricity to flow.

When we add resistance to the rotor circuit, we change the way the motor works. Adding more rotor resistance will make the motor slow down. The more resistance we add, the slower the motor will turn. This gives us a way to control the speed. This resistance helps the motor speed change smoothly. This is great for jobs that need very careful movement.

Changing the rotor resistance is a simple and good way to manage the motor’s speed and torque. The motor can be used to run at a certain speed, not just its fastest speed. It is perfect for jobs that need a changing speed. The fact that you can manage the speed of a wound rotor motor is what makes it so helpful for big jobs in factories. This motor is a real hard worker.

Torque is the twisting force that makes something turn. When you start a motor, you need a lot of starting torque to get things moving. This is especially true if a heavy load is attached. A normal squirrel cage induction motor pulls a very large amount of power from the electrical system to make its starting torque. This can be six to eight times more power than it uses when it is running!

The wound rotor induction motor fixes this problem in a very smart way. To get a high starting torque, we add a lot of resistance to the rotor circuit. We use the resistors on the outside to do this. This does two wonderful things. First, it greatly lowers the amount of starting current the motor needs. This is much better for the electrical system. The amount of starting current is much lower than for squirrel cage motors. The current is lowered, which is a big help.

Second, this added rotor resistance changes the motor in a way that gives the most starting force. The torque is higher because of a better connection between the magnetic fields in the motor. So, we get this huge starting force without a big pull on the power. After the motor is running faster, we can slowly take away the resistance. This lets the motor run well at its top speed. This gives us the best of both things: a strong start and a good run.

You will not find wound rotor motors in your home. These are heavy-duty motors for big jobs. Wound rotor motors are used for jobs that need high starting torque and the ability to control speed. They are perfect for moving very heavy things smoothly and safely.

Here are some common places where you will see these strong rotor motors:

Any job where you need to start a motor with a heavy load is a great place for a wound rotor motor. Also, if you need to control the speed of a motor under a load, this motor is a good choice. These are tough motors for tough jobs.

If we took a wound rotor motor apart, we would see a few main parts. It is a type of induction motor. So, some parts are like its squirrel cage cousin, but the rotor is very different.

All these parts working together make up the full wound rotor induction system. The motor is a simple induction machine. But the special rotor and slip rings give it amazing abilities.

I get this question a lot. A squirrel cage motor is simpler and costs less. It also needs less upkeep. So, why not always use one? The answer is that it is different for each job. For many tasks, a squirrel cage induction motor is the perfect tool. If you need a motor to run a fan at the same speed all the time, a squirrel cage motor is the best pick.

But what if you need to lift something that weighs ten tons? A normal squirrel-cage motor would try to pull a huge amount of power to start. This could turn off the power or hurt the electrical system. It might not even be able to make enough starting torque to lift the weight. The motor might not be able to do the job.

This is where the wound rotor motor works best. It is built for these kinds of tasks. It can create a very high torque when it is not moving, and it uses a low amount of current. This means it can start moving heavy loads without putting stress on the electrical system. So, no, you cannot always use one instead of the other. You must pick the right motor for the task. If you need high starting torque and smooth starts, the wound rotor motor is often the only choice.

In the world of controlling motors, things are always changing. Today, we have a great new tool called a Variable Frequency Drive, or VFD. A VFD is an electronic box that can change the speed of a normal squirrel cage motor. It does this by changing the frequency of the electricity that goes to the motor.

VFDs are used a lot now. They let a cheap and simple squirrel cage motor do jobs that used to need a detailed wound rotor motor. With a VFD, a normal induction motor can have great speed control. It can even make higher starting torque. For many new projects, a person might pick a VFD and a squirrel cage motor instead of a wound rotor motor.

But wound-rotor motors are still needed. They are very tough and can work in very hard places. In some very high-power jobs, a wound rotor motor can still be a better deal for the money or more dependable than a large, detailed VFD system. Also, if you are replacing an old motor in a system that is already there, it is often easiest to use another wound rotor motor. The new variable frequency drives have changed things, but they have not made the tough old wound rotor motor no longer needed.

To finish, let’s look at the good things and the bad things. Just like any tool, the wound rotor induction motor has its good points and its bad points. It is important to know both before you decide if it is the right motor for what you need.

Advantages (Pros):

Disadvantages (Cons):

Knowing these points will help you see why this motor is a special tool for special jobs. It is not for every task, but when you need its special strengths, no other motor will work as well.

I hope this has helped you learn about the wound rotor induction motor. It is a very interesting machine in the world of electric motors. Here are the most important things to remember: