Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

I’ve been in the manufacturing business for a long time. I’ve seen companies thrive and I’ve seen them struggle. And often, the difference comes down to the smallest parts. In this article, I’m going to talk about one of those small but mighty parts: the motor shaft. You’ll learn what a shaft is, how it works, and why a poorly made shaft could be costing you a fortune in repairs and downtime. This guide is for you if you’ve ever dealt with a failing electric motor and couldn’t figure out why. I’ll show you how choosing the right shaft can save you from these headaches.

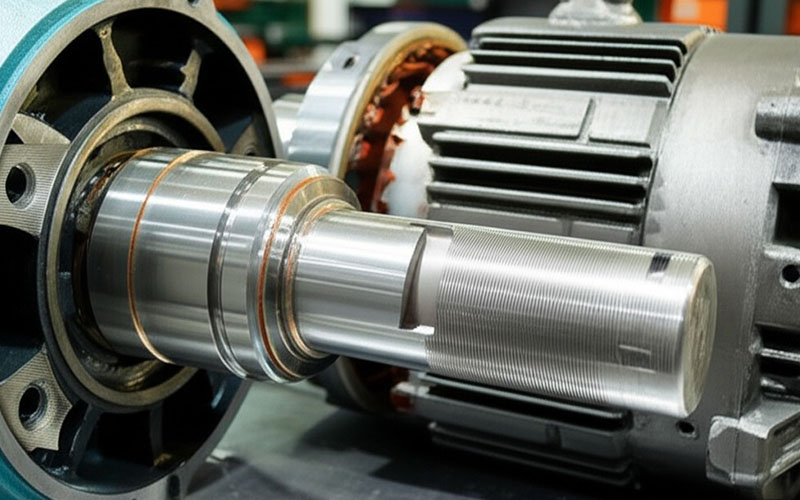

Have you ever looked at an electric motor and wondered how it makes things move? The magic happens with a simple part called the motor shaft. Think of it as the backbone of the motor. A motor shaft is a cylindrical component that sticks out of the motor and its housing. Its main job is to take the power from inside the motor and deliver it to the outside world. Without a good shaft, the motor is just a box of wires that hums. The shaft is the bridge between electrical energy and useful work.

The problem is, many people overlook the shaft. They see a big, expensive electric motor fail and assume the whole thing is bad. They replace the entire motor, costing them time and money. But the real issue is often a weak or poorly designed motor shaft. This simple-looking rod has to handle incredible stress, torque, and rotation. If it’s not up to the task, it will fail.

That’s where we come in. Over the years, I’ve seen countless mechanical failures caused by a bad shaft. We specialize in making precision pins and shafts that are built to last. A quality motor shaft isn’t an expense; it’s an investment in the reliability of your entire machine. A strong shaft ensures that the power from the motor gets where it needs to go, smoothly and efficiently. The shaft is essential for the long life of any electric device.

The main function is to transfer power. The electric motor does the hard work of converting electrical energy into mechanical motion. But that motion is useless if it stays inside the motor. The functions of electric motor shafts are all about delivery. The shaft takes the rotational force, or torque, created by the motor and transmits it to another part, like a gear, pulley, or coupling. This is called power transmission. The shaft is the final step in this energy conversion process.

This job puts a lot of pressure on the motor shaft. It has to support the weight of the components attached to it. It also has to handle the twisting force of the torque. Imagine trying to twist a metal rod with your bare hands. Now imagine a powerful motor doing that thousands of time per minute. The shaft must be strong enough to handle that force without bending or breaking. The transmission of power must be perfect.

A high-quality shaft does more than just spin. It provides a stable axis for the rotating parts of the machine. It holds everything in the right position. This stability is key for optimal performance and long life. When you choose a shaft from us, you’re choosing a component designed for perfect power transmission. We ensure every shaft can handle the high torque and stress of your motor applications, protecting your investment.

Let’s look inside an electric motor. You have coils of wire and magnets. When electricity flows through the coils, it creates a magnetic field that pushes against the magnets. This creates a rotational force. The part that spins is called the rotor, and the motor shaft is connected directly to it. In fact, in many types of motor, the shaft is the core of the rotor itself. The shaft runs through the center of the motor, supported by a bearing on each end.

This setup is simple but very important. The shaft connects the inside of the motor to the outside world. As the rotor spins, the shaft spins with it. This is how electric motors work. They turn electrical energy into mechanical motion, and the motor shaft is the part that delivers that motion. The end of the shaft that sticks out of the motor is called the output shaft. This is where you connect your other mechanical components.

This design means the motor shaft must be perfectly straight and balanced. If the shaft is even a little bit bent, it will cause huge problems. It will wobble as it spins, creating vibration that can damage the bearing system and other delicate motor components. This is why precision engineering is so important. We build our shafts to be perfectly straight and strong, ensuring they spin smoothly. A precise shaft protects the entire motor and keeps your machine running.

Here’s a question I ask a lot of my clients: “How often do you check your motor shaft alignment?” The answer is often “never.” This is a huge, costly mistake. Shaft alignment is the process of making sure the motor shaft is lined up perfectly with the shaft of the device it’s driving. When shafts are misaligned, even by a tiny amount, it creates a massive amount of stress.

Think about it this way. You have two spinning rods that are supposed to be in a perfect line. If one is slightly higher or at an angle, they will fight against each other with every rotation. This fight creates friction, heat, and vibration. It wears out your motor parts, especially the bearings and the coupling. You start to see seals leak. You hear strange noises. Before you know it, you have a complete failure of the motor.

This is a problem that silently drains money from your business. The extra vibration and friction from misalignment also waste energy, driving up your electricity bills. You’re paying for power generated by the motor that is being lost to destructive forces. The solution is simple: regular motor shaft alignment. And it starts with a well-made shaft. A perfectly machined shaft makes alignment easier and more reliable. Our shafts are made with precision, giving you a solid foundation for a healthy mechanical system.

When a motor shaft and the driven equipment shaft are not lined up, it’s called shaft misalignment. This is one of the biggest causes of mechanical failures in rotating machinery. The misalignment forces the shaft to bend with every single turn. This constant flexing will eventually cause the shaft to crack and break. It’s like bending a paperclip back and forth until it snaps.

The damage doesn’t stop at the shaft. This constant stress is transferred to other parts. The bearings that support the shaft take a huge beating. Misalignment is the number one cause of premature bearing failure. The coupling that connects the two shafts is also put under strain it was not designed for. This can lead to the coupling failing, which can be very dangerous if it happens while the machine is running at high speed.

The most obvious sign of shaft misalignment is excessive vibration. If your machine is shaking more than usual, misalignment is a likely cause. This vibration can loosen bolts, crack welds, and damage other parts of your machine. It’s a chain reaction of destruction that starts with two shafts that are not in line. By using a flexible coupling and ensuring proper alignment of the motor, you can prevent this. A high-quality shaft from us makes this process much easier, as it provides a true, straight reference point to align to.

A coupling is a small but critical device. Its job is to connect the motor’s shaft to the shaft of another machine, like a pump or a gearbox. This allows the motor shaft to transfer its rotational power. The coupling is the bridge between the motor and the mechanical components it drives. There are many types of couplings, but they all serve this basic purpose.

One important type is the flexible coupling. No alignment is ever absolutely perfect. Flexible couplings are designed to handle tiny amounts of misalignment. They can bend or flex a little to absorb the stress of a slight misalignment. This protects the motor shaft and the bearings from damage. However, a flexible coupling is not a fix for a bad alignment job. It is only there to handle the tiny errors that are impossible to eliminate.

Choosing the right coupling is just as important as choosing the right shaft. The coupling must be able to handle the torque from the motor shaft. If the torque applied to the shaft is too high for the coupling, it will fail. We can help you think about your entire system. A great motor shaft deserves a great coupling. Together, they form a strong and reliable team for torque transmission, making your mechanical systems more robust.

Not all motor shafts are the same. The end of the shaft, where it connects to the coupling or gear, comes in different shapes. The shape you need depends on your application. The selection and design of the shaft are critical. Knowing the different types of motor shafts can help you choose the right one. Let’s look at a few common types.

One common type is the keyed shaft. This shaft has a slot, called a keyway, cut into it. A small metal piece called a key fits into this slot and a matching slot in the coupling. This key locks the two parts together, ensuring they spin as one. This is a simple and effective way to transmit torque. Another type is the D-shaft, or flatted shaft. Here, one side of the cylindrical shaft is ground flat. This flat surface gives a setscrew a place to grip, preventing the shaft from slipping.

Other types of shafts include the splined shaft. A splined shaft has a series of grooves or teeth along its length that match up with grooves in the coupling. This design can handle a large amount of torque and is very strong. There is also the hollow shaft. As the name suggests, this shaft is a tube instead of a solid rod. It is lighter than a solid shaft and can be useful in applications where weight is a concern. We manufacture all these shaft types with extreme precision, ensuring your machine has the perfect motor shaft for the job.

The material used to make a motor shaft is incredibly important. The shaft needs to be strong enough to handle torque and stress, but also durable enough to last for years. The most common material for motor shafts are typically made of steel. But not all steel is the same. The two most popular choices are carbon steel and alloy steel.

Carbon steel is a great all-around choice. It is strong, hard, and relatively inexpensive. For most standard motor applications, a carbon steel shaft is a reliable and cost-effective option. It provides the strength needed for normal operation. We use high-quality carbon steel to make sure even our standard shafts outperform the competition. A good steel shaft is the foundation of a good motor.

For more demanding jobs, alloy steel is the better choice. Alloy steel is carbon steel that has other elements added to it, like chromium or nickel. These additions give the steel special mechanical properties. An alloy steel shaft can be much stronger and tougher than a carbon steel one. It can handle higher torque, more heat, and more impact. If your machine operates under extreme conditions, an alloy steel shaft provides extra reliability and peace of mind. We can help you decide which material is right for your needs, ensuring your motor shaft never lets you down.

When you are looking at materials for motor shafts, you need to think about their mechanical properties. These properties tell you how the material will behave under stress. The most important property for a shaft is strength. The shaft must be strong enough to transmit torque without bending or breaking. This is often called tensile strength.

Another key property is hardness. A harder shaft is more resistant to wear and tear, especially in the areas where it contacts a bearing or a seal. However, a material that is too hard can also be brittle, meaning it might crack under a sudden impact. So, there needs to be a balance. The motor shaft design must consider both strength and toughness. Toughness is the ability of the shaft to absorb energy without fracturing.

The shaft dimensions are also a critical part of its mechanical performance. A thicker shaft is stronger than a thinner one. The length of the shaft also matters. The goal of a good motor shaft design is to find the perfect balance of material, hardness, and size for the job. Our engineers have decades of experience in this. We design shafts that have the ideal mechanical properties for superior performance and reliability in your motor systems.

So, how does all this help you? Let’s bring it all together. You run a business that depends on machines. When a machine breaks down, you lose money. A common point of failure is the electric motor’s power transmission system. The problem often starts with a low-quality motor shaft. A weak, poorly made, or misaligned shaft is a ticking time bomb. It creates vibration, destroys bearings, and eventually leads to a catastrophic failure.

The frustration is immense. You replace the entire motor, but a few months later, the same thing happens. The costs add up. The downtime is killing your productivity. This is the pain caused by ignoring the importance of one small part. The shaft is a mechanical component that is at the heart of your operation.

The solution is to invest in quality from the start. A high-quality, precision-made motor shaft is the answer. By using a shaft made from the right material with the right mechanical properties, you eliminate the root cause of many failures. Proper shaft alignment improves the life of all your motor parts. Our shafts are designed to provide a solid, reliable foundation for your mechanical parts. This means less vibration, longer bearing life, and fewer unexpected breakdowns. A better shaft leads to a better, more reliable machine, saving you time, money, and stress.

To make sure your electric motors run for a long, long time, remember these key points about the motor shaft: