Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

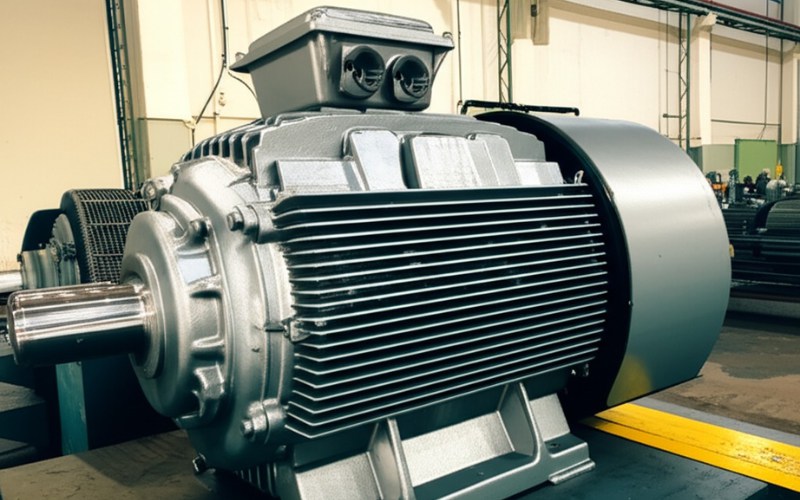

You might work with big devices. These are AC and DC rotating machines. You see them in big job locations, like a factory. This equipment will help you do hard work. You will learn how to take a machine apart. You will also learn how you put a new machine back. This is great to recognize. It assists in maintaining the machines running well. It helps operations continue. This short article is worth checking out if you intend to learn about how, as a professional, you will work with these essential devices. Keep reading, and discover!

You will see numerous types of machines in your work. Some use AC power. Some use DC power. AC implies the power goes back and forth. DC implies the power goes one method. This is also called direct current. Both AC and DC electric motors are a type of electric motor. They transform power right into spin. This spin can function. This equipment is used in many commercial locations. A good specialist learns about both AC and DC types. The power supply for these machines is very strong. These rotating machines have many components. One key component is the rotor. The rotor is the part that rotates. Another part is the winding. The winding is made of wire. When power is supplied to the winding, the rotor can turn. It is important for you to know the specifications of each machine. This assists with any type of repair work. The power supply has to match the device. You should always check the documentation for the machine. This tells you about the power supply and other demands. The devices you use will depend on the machine type.

An electrical motor can get damaged. This is a failure. When a machine fails, it stops working. This can cause downtime. You will want to avoid downtime. So, you will need to fix the electrical motor. A fix can solve the problem. Often a tiny component is the cause of the failure. The repair service can be big or small. The goal of a repair is to make the machine operate well again. A good repair can make the machine last a long time. This saves money for the customer. You may see many reasons for a machine failing. A bearing can wear out. The winding can melt. A wire could be damaged. Excessive load on the machine can cause a failure. Inadequate clean air can make it too hot. A good technician can find the reason for the failure. After that, you can do the appropriate repair. You will test the device after a repair. The power supply should be off for most repair work. Safety is a large part of any repair task on an electric motor. This is essential for you as the specialist and for the equipment.

First, safety! Before you remove any machine, you must shut off the power supply. This is so vital. You will detach the power supply from the machine. You must check to make sure there is no electric power. You will use a special tool to test this. After that, you will disconnect the cables. You will label each wire and cable. This helps when you install the new machine. You should also check if the machine is hot. A hot machine can cause burns. Next, you will check how the machine is held in place. Some machines are very heavy. You may need special tools to lift the machine. This might be a hoist or a small crane. You will remove any bolts that hold the device down. Be careful when you remove the equipment. You do not want to injure yourself. You do not want to harm other devices. The removal of the machine needs a plan. You must follow the instructions for removal. This procedure is necessary for a safe removal. You must detach all power sources.

A bearing is a small part. Yet it is a big deal in an electrical motor. You should always examine the bearing. The bearing helps the shaft of the equipment rotate. It lets the shaft spin very easily and smoothly. If a bearing is bad, the device will not rotate well. The motor’s operation will be inadequate. You might hear a loud sound. Or the machine might overheat. A bad bearing can cause a big failure. You will often need to fix or change a bearing. This is typical repair work for industrial equipment. To change a bearing, the power supply needs to be off. As the technician, you will remove the old bearing. Then, you will install a new bearing. The new bearing needs to be the correct size. The size is crucial. It must be a precise fit. A good bearing helps the machine run for a long time. It can extend the lifespan of the electric motor. A bearing needs to be clean too. Dirt and debris are bad for a bearing. Each bearing component must be correct.

An electric motor uses power to make something rotate. Almost all that spins is called the shaft. The rotor is on the shaft. When electric power from the power supply is supplied to the winding, it creates an electromagnetic force. This force makes the rotor and shaft turn. This turn is called torque. Torque is the twisting force that makes the equipment do work. The machine can connect to other devices. This tool does a job. For instance, it might drive a fan. Or it might lift a heavy load. The way the device can turn and the torque it can make are in its specifications. The power supply provides energy. The equipment transforms this energy into motion. This is the basic operation of an AC and DC electric motor. The connection to the load must be strong. A good technician will check this connection. The cable must be the correct gauge/size.

Sometimes, the wire inside an electrical motor gets damaged. This wire is called the winding. If the winding is bad, the motor might not run. Or it might not run well. This is a common failure in an old machine. When this happens, you may need to rewind the motor. A rewind means you remove the old wire. Then you put in new wire. This is a big repair. A rewind is a job for an expert specialist. It requires special skills and unique tools. You, as the technician, must know the proper way to place the new winding. The new wire needs to be the appropriate type and size. This conductor must carry the electric power. After the rewind, you will test the motor. A good rewind can make an old motor like new. It can save the cost of new equipment. The power supply is checked with the rewound motor. You will also check the insulation of the new winding. This rewind procedure extends the motor’s lifespan.

A machine needs to be clean to work well. Over time, dirt and debris can get into the equipment. This can make the machine hot. It can also harm parts like the bearing. So, you should always clean your equipment. This is part of good maintenance. A clean machine will operate with better operational efficiency. To clean a machine, you must first ensure the power supply is off. You will use a brush or a vacuum cleaner to remove loose dust. Often, you will use special cleaning fluid. Take care not to get water in the electrical components. You will clean the outside cover of the machine. You should also try to clean the internal parts if you can reach them. A clean machine looks good. More importantly, clean equipment runs better. It is less likely to fail. A good professional will always clean the work area and the machine. This helps find problems too.

Before you install a new electric motor, you must inspect several things. First, you will inspect the new machine. Is it the correct one? You will look at the specifications. Does it match the old machine? You will check the shaft size. You will examine the mounting holes. The configuration has to be correct for the application. The power supply requirements are very important. You should also check the area where the machine will go. Is it clean? Is it ready? You will look at the foundation. It should be strong and flat. The alignment of the equipment is very important. If it does not line up well, it can cause vibration. This vibration can harm the new machine or the equipment it drives. You will inspect the electrical connection points. Are the wires and cables ready? A good inspection before installation saves time. It helps the install go smoothly. The power sources must be ready to connect.

To install an electric motor, you should follow a clear procedure. First, you must ensure the power supply is off. Safety first, always! You will carefully move the new device into place. You will use the correct tools to lift it if it is heavy. After that, you will align the machine. This means you make sure it lines up perfectly with the equipment it will drive. Accurate alignment is very important. Next, you will bolt the machine down. The bolts must be tight. After that, you will connect the electrical cables. You must ensure each wire is connected to the correct terminal. The connection should be strong. You will use the correct tool to tighten each connection. You will check the wire/cable size again. You should check the documentation to properly connect the power supply. After all connections are made, you will place any covers back on the machine. This installation process needs to be done by a trained service technician. To install properly means the equipment will run well.

After you install a new device, the job is not done. You must test the device. The test is very important. It tells you if you did the installation right. It shows if the device will operate as it should. The power supply is now ready to be turned on for the test. Be very careful when you first switch on the power supply. First, you will check if the machine starts to rotate in the correct direction. You will listen for any odd sounds. You will look for excessive vibration. You will let the machine run for a bit. You will check if it gets too hot. You may use a special tool to measure the electrical load. This test helps you to make sure the device is safe. It also helps you make sure it will do its job well for the customer. A good test means a good installation. If the test shows a problem, you will find it and repair it. Then you will test again. You want the machine to be functional and produce good results. You want the customer to be pleased with the new machine. As the technician, you should certify the installation is good.