Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

We are Sino, a top maker of very precise stator laminations in China, and we are proud to lead the way in new electric motor technology. Our dedication to high quality, modern production skills, and strong understanding of materials help us work with many different customers around the world. These include new and leading electric car makers, producers of strong industrial machines, suppliers of important parts for airplanes and spacecraft, and companies building big renewable energy projects.

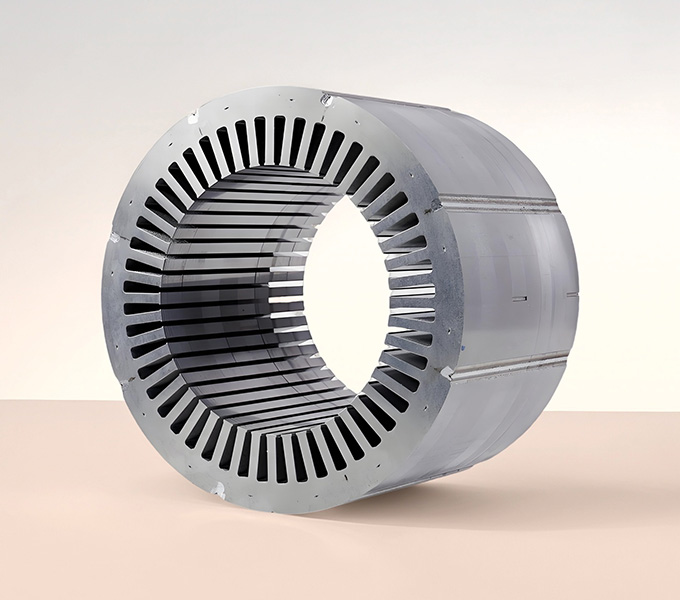

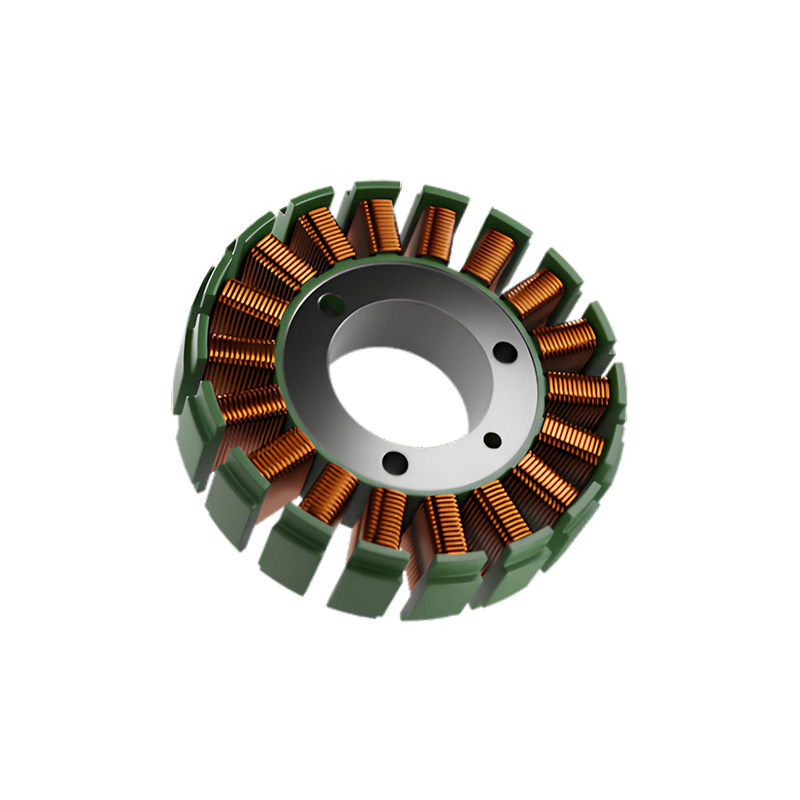

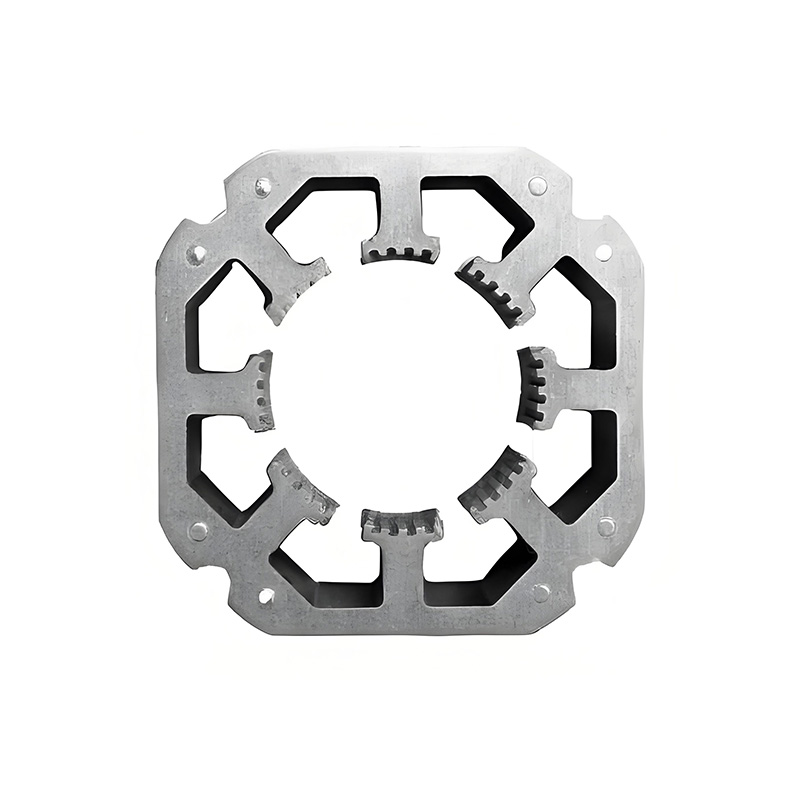

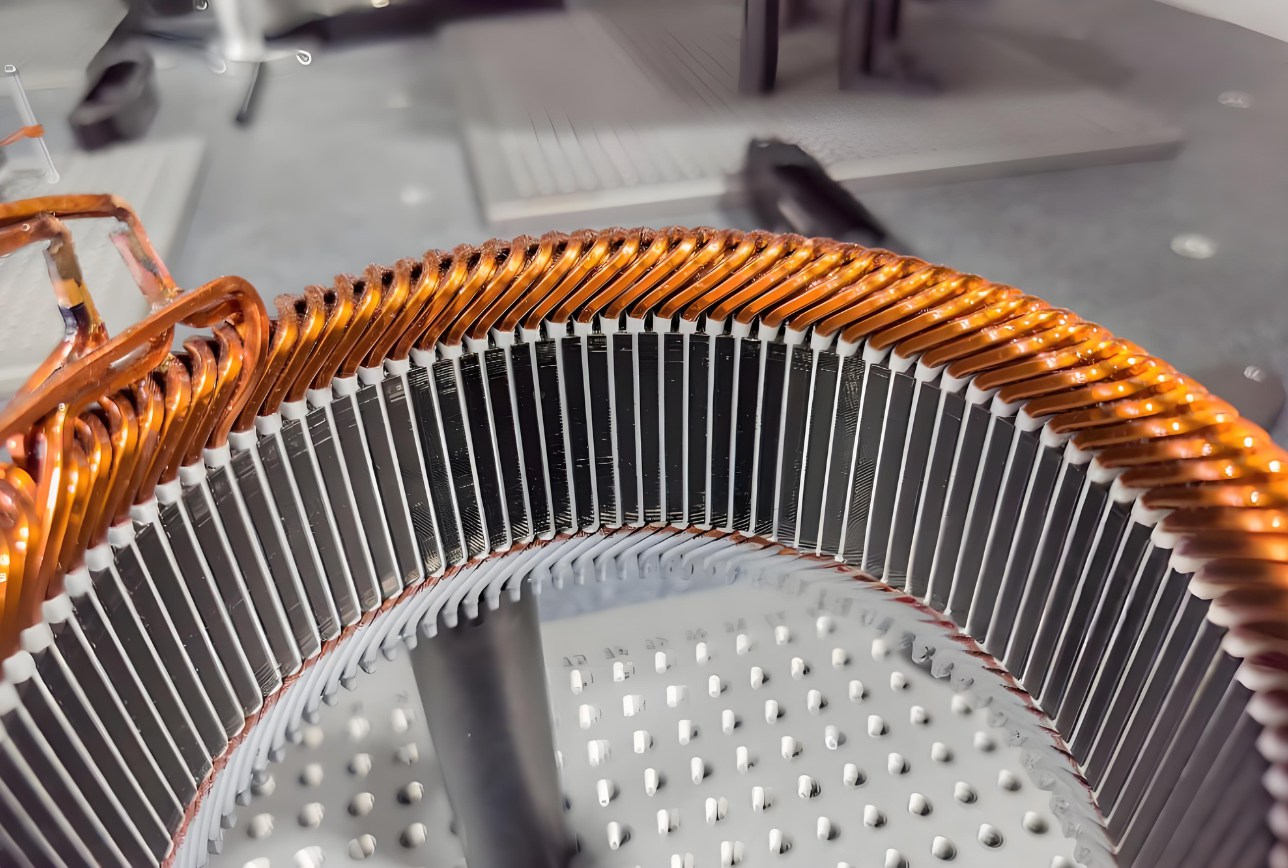

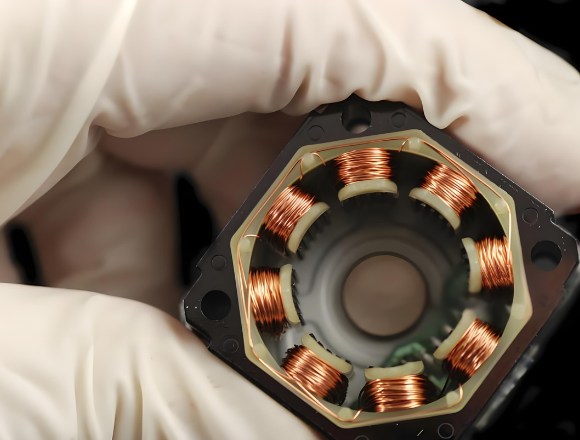

Stator laminations are thin, coated sheets of electrical steel, carefully stacked and put together to make the stator core. This core is the non-moving part of an electric motor, and it holds the coils of wire that create or work with the magnetic field. Their main job is to give the magnetic field an easy path to follow, while also cutting down on energy waste that would badly hurt how well the machine works. The main reason for using thin laminations instead of a solid iron core is to fight two main types of energy loss in the core: eddy current losses and hysteresis losses.

We meticulously craft our stator laminations from thin, specialized sheets of electrical steel. Each sheet is electrically insulated from its neighbors. This construction effectively slices and dices the paths available for those eddy currents. The thinner the lamination, the more effectively we can choke off these losses.Of course, thinner laminations mean more sheets for a given stack height, which can increase manufacturing complexity and cost. There’s also the “stacking factor” – the ratio of actual magnetic material to the total volume (including insulation). At Sino, we help you navigate this balance. We might advise a customer developing a high-efficiency industrial pump motor that 0.35mm laminations offer the sweet spot for their target IE4 efficiency rating, considering both performance and cost-effectiveness.

The steel we employ for your stator laminations is a highly specialized material known as electrical steel, often a silicon-iron alloy, and its selection is a cornerstone of our design and manufacturing philosophy at Sino.

Choosing the right grade is paramount because different steels bring different magnetic personalities and loss characteristics to the table.

Silicon (typically we see it in amounts up to around 3.5% for many motor grades) significantly boosts the steel’s electrical resistivity. It also plays a role in taming another form of energy loss called hysteresis loss, which is related to the energy it takes to re-magnetize the core material with each cycle of the alternating current. However, there’s a trade-off: pile in too much silicon, and the steel can become quite brittle, making it a headache to punch cleanly during manufacturing. At Sino, we source materials that hit that ideal blend of electrical performance and mechanical workability.

For most stator laminations in rotating machinery, we’ll recommend non-oriented electrical steels. Non-oriented steels offer good magnetic properties in all directions within the plane of the lamination. (Grain-oriented steels, which are magnetically supercharged in one direction, are more the domain of transformer cores where the flux path is more predictable).

Impurities within the steel or internal stresses leftover from the steel mill’s rolling process or, crucially, from the punching process itself, can act like magnetic roadblocks, degrading performance. A post-punching annealing step relieves those stresses, “healing” the material and restoring its optimal magnetic mojo. Sino’s process includes meticulous attention to annealing when the material and application demand it.

The material you choose is very important for how well stator laminations work. At Sino, we offer a wide range of modern materials. Each one is picked and prepared to get the best magnetic, heat-related, and physical properties for many different uses.

The main material we offer is electrical steel, mostly silicon steel, because it has great magnetic abilities and is a good price.

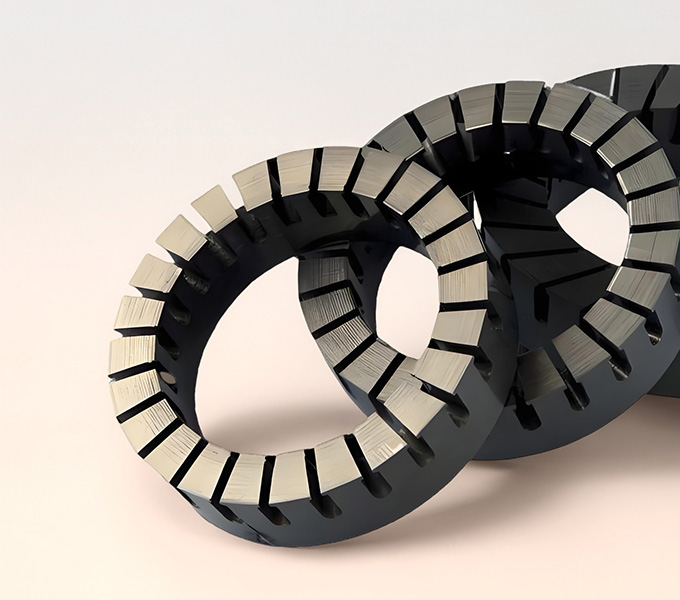

Non-Grain-Oriented (NGO) Silicon Steels: These are the usual choice for motors that spin. NGO steels have magnetic properties that are the same in all directions. This means their magnetic performance is the same no matter which way the magnetic field points. This is very important for spinning motors where the magnetic field spins inside the stator core. Sino uses different types of NGO steels, including some with more silicon for better electrical resistance and less energy waste in the core. We also use thinner sheets (like 0.20 mm, 0.27 mm, 0.35 mm) to better stop eddy currents, especially in uses where things happen very fast, like in EV traction motors.

Grain-Oriented (GO) Electrical Steels: These are mostly used in transformers because their properties are different in different directions (they work best when the magnetic field is in one specific direction). GO steels are sometimes used for certain linear motors or special spinning motors where the magnetic field mostly travels in one direction. But for most spinning motors, NGO steels are the better choice because their properties are the same in all directions.

For jobs that need very, very low energy loss, especially at high speeds, Sino looks into and works with modern materials like amorphous metals and nanocrystalline alloys.

Amorphous Metals: These materials have a jumbled-up atom structure, not a neat pattern. This leads to very good electrical resistance and very low hysteresis losses. They are usually made as very thin strips (like 20-30 µm). While they have better magnetic abilities, they break easily and are hard to work with to make complex shapes. This means they are only used in special, high-efficiency, or high-speed areas for now.

Nanocrystalline Alloys: Made from amorphous materials by carefully heating them, these alloys (like Vitroperm, Finemet) have both high electrical resistance and a better ability to carry a magnetic field. They show very low energy loss even with strong magnetic fields and at high speeds. Just like amorphous metals, they break easily and are hard to work with, which limits their use to special jobs for now. But Sino is actively researching how to use them in future high-performance motors.

Sino sees the great new possibilities of Soft Magnetic Composites (SMCs) for new motor designs. SMCs are made of magnetic powder bits. Each bit is coated with an insulating layer, and then they are pressed and heated to make a solid part.

Same Properties in All Directions and 3D Magnetic Path Design: A key benefit of SMCs (like Höganäs’ Somaloy series, Carpenter Technology’s Ancorbond) is that their magnetic properties are the same in all directions. This allows for new kinds of motor designs with complex, truly three-dimensional magnetic paths. This isn’t possible with normal stacked steel because of their one-directional properties and the limits of stacking. This allows for new motor designs like axial flux motors and transverse flux machines.

Performance Numbers: While SMCs are generally not as good at carrying a magnetic field (typically 200–600 vs. 1500–4000 for NGO steels) and have more energy loss at speeds above 1 kHz compared to normal electrical steels, their design freedom can make the whole system more efficient. For example, Somaloy 700 3P has a typical ability to carry a magnetic field of ~400 and energy losses of 40–60 W/kg at 1.5 T, 400 Hz.

New Materials and Processes: Sino keeps up with new developments in SMC technology. This includes better powder particle sizes, improved insulation coatings (like nano-oxide or phosphate layers), and better pressing/heating methods to make them denser and reduce energy loss. We are ready to work with customers who are looking into SMC solutions for their special design needs.

The performance of stator laminations doesn’t just depend on the magnetic material; the insulation and glue used to hold them together are just as important.

Insulation Coatings: To stop eddy currents from flowing between the thin sheets and to keep electricity from crossing over, each lamination is coated with an insulating layer. Sino uses several modern coatings, including non-organic (like phosphate, oxide) and organic (like varnish) types. For high-temperature airplane and spacecraft jobs (above 180°C), we use systems based on polyimide and ceramic fillers that are rated to work non-stop at 220–250°C. They keep their electrical insulation and stickiness even in tough conditions. New sol-gel and nano-ceramic coatings are also being looked at for their ability to move heat well and resist high voltages.

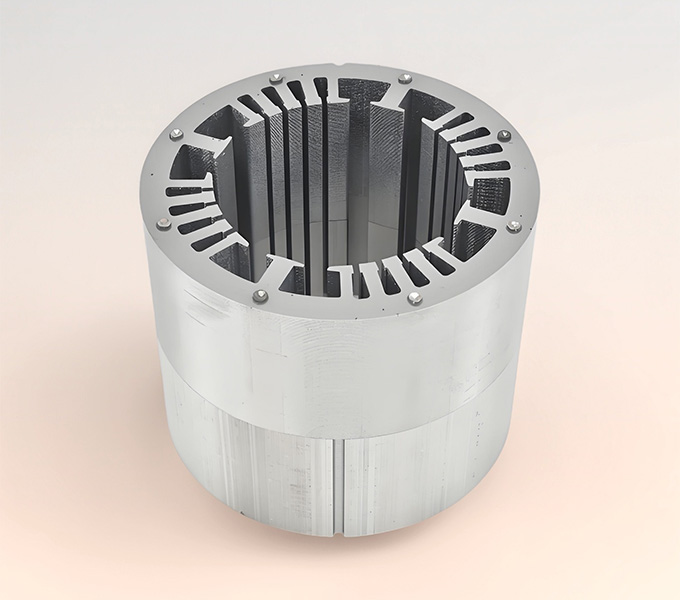

Bonding Agents: After stacking, the laminations must be stuck together firmly to make a solid core. Common ways to do this are interlocking, welding, and gluing. Sino knows the pros and cons of each:

Interlocking and Laser Welding: These methods provide better heat flow through the stack (up to 30% more than gluing) and good strength. However, they can sometimes create small paths for eddy currents and cause stress in the material.

Adhesive Bonding: While gluing offers great electrical insulation and reduces shaking, old types of glue with low heat flow can block heat from getting out. Sino uses modern epoxy and silicone-based glues with a better ability to move heat (up to 4 W/m·K) to help heat travel from the core to the motor case, especially for airplane and spacecraft jobs. Mixed methods, like combining spot welding with high-heat-flow glues, are also being studied to get a good mix of heat handling and strength.

At Sino, our knowledge of materials means we can suggest and use the best material and insulation/gluing system for your specific job, balancing performance, cost, and how easy it is to make.

To give you a clearer picture, here’s a simplified look at some common electrical steel considerations Sino manages:

Material Grade Aspect | Sino’s Approach & Considerations | Typical Scenarios |

Silicon Content | Selected based on target efficiency, frequency, and cost. Higher Si for lower losses, balanced against punchability. | Low-Si for cost-sensitive, lower-freq motors; High-Si for high-efficiency designs. |

Lamination Thickness | Optimized from 0.1mm to 0.65mm (or thicker for specific low-frequency scenarios). Thinner for high frequency and lower losses. | 0.5mm/0.65mm for 50/60Hz general motors; 0.2mm/0.35mm for higher efficiency/frequency. |

Coating Type (Insulation) | Offering various coatings (C3, C4, C5 per ASTM A976) for optimal insulation, punchability, and heat resistance. | C3 for general purpose; C5 for applications requiring stress-relief annealing. |

Stress-Relief Annealing | Applied post-punching for sensitive materials or high-performance stacks to restore magnetic properties affected by work-hardening. | Crucial for high-permeability steels and where minimal core loss is paramount. |

Purity & Sourcing | Sino partners with reputable steel mills, ensuring consistent quality and traceable material certifications. | All critical applications, especially aerospace, medical, and high-performance EV. |

The interlaminar insulation is so critical. At Sino, we work with a range of industry-standard coatings, often classified by standards like ASTM A976. These include:

Dull or poorly designed tools create burrs which effectively increase the ‘electrical thickness’ of the lamination locally, boosting eddy current losses and reducing the stacking factor. At Sino, our rigorous tool maintenance schedules and investment in high-quality carbide tooling mean burr height is kept to an absolute minimum, often measured in mere microns.

For prototypes, highly complex geometries, or small-batch runs where creating a dedicated stamping die isn’t economical, Sino also has capabilities with laser cutting or even wire EDM for ultimate precision. While laser cutting can create a small heat-affected zone (HAZ) at the cut edge that might slightly alter local magnetic properties, it offers incredible flexibility. We often counsel clients on when this trade-off makes sense, for example, during the rapid prototyping of a novel motor design for a medical device.

For many high-performance stator core laminations, a crucial step after punching is stress-relief annealing. Sino’s annealing processes are tightly controlled to ensure optimal results without damaging the vital interlaminar insulation (especially when using C5 or similar high-temperature coatings).

The precision Sino brings to every step – from material inspection to final stack measurement – ensures that the stator lamination stack you receive isn’t just a collection of steel sheets, but a highly engineered component ready to deliver peak performance.

1

Sino employs advanced welding techniques, including TIG and laser welding, with precise control to minimize these risks.

2

Sino has extensive experience in designing and producing interlocked stator lamination stacks.

3

In some advanced or specialized scenarios, laminations can be bonded together using adhesives. This can offer excellent interlaminar insulation and mechanical damping but is often a more complex and costly process.

4

Sometimes, particularly for very large machines or certain repair scenarios, stacks are held together by bolts passing through holes in the laminations (which must be insulated) or by external clamping plates.

Beyond the material, thickness, and insulation, the actual physical shape of each individual stator lamination is meticulously engineered. At Sino, we don’t just stamp out parts. We can work from your detailed drawings, or our experienced team can collaborate with your design engineers, offering insights into how lamination geometry choices might affect manufacturability or even suggest subtle tweaks based on our extensive experience that could enhance performance or reduce cost.

Sino’s customers around the world are in many different industries. Each has special needs and performance goals for electric motors. We are good at creating stator lamination solutions that are just right for these specific job needs, making the material properties, manufacturing accuracy, and core design as good as possible.

The EV industry needs a lot of power in a small space, high efficiency over a wide range of speeds, and good performance even when conditions change quickly.

High-Speed Operation: EV motors often spin at high speeds, which leads to high electrical frequencies. This means we need ultra-thin laminations (e.g., 0.20 mm or even 0.18 mm) made from top-grade NGO silicon steels with more silicon to reduce eddy current losses.

High Power in a Small Space: To make small and powerful motors, we need high magnetic fields. We use high-saturation electrical steels that can work up to 2.1 T before the magnetic field gets too full.

Heat Management: The high power in EV motors creates a lot of heat. We support designs with modern cooling features, including better slot shapes for cooling the wires and thinking about adding direct liquid cooling.

Ability to Make Large Quantities: For EVs that are made in large numbers, high-speed stamping is the best way to make parts because it is very fast and low-cost. Sino’s ability to do large-scale stamping is perfect for this market. For making quick first models and early designs, laser cutting provides the needed flexibility.

Industrial jobs value being dependable and lasting a long time, as well as being highly efficient when running all the time, often at lower speeds than EVs.

Efficiency and Long Life: Standard NGO silicon steels (e.g., 0.35 mm, 0.50 mm) are often used to balance cost and efficiency. The focus is on a strong structure that can handle running all the time and keep shaking to a minimum.

Customization: Industrial motors often have specific power levels and shapes. Sino provides custom lamination designs and manufacturing, using both stamping and laser cutting depending on how many are being made.

Strength Against Heat: While not as tough as aerospace jobs, industrial motors need good heat removal. Our choice of insulation and glues ensures they stay stable with heat and perform well for a long time.

Aerospace jobs have the toughest needs for weight, power in a small space, efficiency, and tough environments (temperature, vibration).

Very High Power in a Small Space and High Efficiency: This makes it necessary to use the thinnest possible laminations (e.g., <0.2 mm) and possibly modern materials like amorphous or nanocrystalline alloys for very low energy loss, even though they are hard to work with.

Extreme Heat Management: Aerospace machines work at high temperatures (e.g., 180–250°C). Sino offers solutions with:

Mechanical Strength and Fatigue Life: Aerospace jobs involve heating up and cooling down often and high vibration. We focus on bonding methods that ensure they last a long time, often choosing flexible, high-temperature glues over stiff welding for better durability.

Weight Reduction: Every gram is important. Our design process looks at material density and shape efficiency to make the final part as light as possible.

Traceability and Certification: Sino follows very strict quality rules and paperwork processes needed for aerospace certification.

Wind turbine generators are known for being very big, running at low speeds, and focusing on getting the most energy while needing little maintenance.

High Efficiency at Part Load: Wind turbines work across a wide range of wind speeds, so being efficient at partial loads is very important. High-grade NGO steels are used to keep core losses low.

Large Diameter Laminations: These generators need very large diameter laminations, which are often made in segments for manufacturing and transport. Sino is able to make and accurately put together these large segments.

Strength and Long Life: Because they are in far-away places and have long working lives, the laminations must be very durable and able to resist damage from the environment.

Cost-Effectiveness: While efficiency is important, the large amount of material used means that being cost-effective is also a big factor.

SMC technology, while having higher core losses at high speeds, is useful in special situations where its special benefits are more important than its weaknesses:

3D Magnetic Path Motors: Axial flux motors, transverse flux machines, and integrated electromagnetic actuators get a big help from the all-directional properties of SMCs, which allows for compact and new designs not possible with normal laminations.

Automotive Electric Power Steering (EPS) Motors: SMCs are being used more and more here because they can create compact, efficient designs with fewer assembly steps.

Small Traction Motors and High-Speed Compressors: In these jobs, the design freedom and the potential to reduce system size and weight offered by SMCs can be a key reason for choosing them.

Reduced Assembly Steps: SMCs are typically made using powder metallurgy, which allows for making parts that are almost the final shape. This reduces the need for multiple assembly steps (stacking, welding, interlocking), leading to possible cost and time savings for low- to medium-volume production or custom designs.

Sino’s good understanding of these different job needs, combined with our wide range of materials and manufacturing skills, makes us a very helpful partner for motor makers around the world. We don’t just sell laminations; we give you custom solutions that improve how things work and create new ideas across industries.

When you boil it all down, creating a top-tier electric motor or generator demands excellence in every component. And as we’ve seen, the stator laminations are far more than just passive pieces of metal; they are active participants in the energy conversion process.

Choosing Sino for your stator core laminations and stator lamination stacks means you’re not just buying a part; you’re gaining a partner dedicated to:

From raw material verification to final dimensional checks, quality is woven into our DNA.

We understand the metallurgy, the electromagnetics, and the manufacturing intricacies.

Our investment in top-tier tooling, machinery, and processes translates directly into superior laminations for you.

Whether you have a fully detailed design or need guidance optimizing for a specific scenario, we're here to work with you.

We know you count on timely delivery of consistent, high-quality components to keep your production lines running.

The efficiency, power density, and longevity of your electric machines are significantly influenced by the often-unseen stator laminations within. Don’t leave this critical component to chance. Talk to Sino today, and let’s power up your performance together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.