Lassen Sie Sino's Lamination Stacks Ihr Projekt verstärken!

Um Ihr Projekt zu beschleunigen, können Sie Lamination Stacks mit Details wie Toleranz, Material, Oberflächengüte, ob eine oxidierte Isolierung erforderlich ist oder nicht, Mengeund mehr.

Ein nanokristalliner Kern ist eine bestimmte Art von Bauteil. Man kann ihn in vielen elektronischen Geräten finden. Er ist der Hauptbestandteil einer neuen Art von Transformator. Dieser Kern hilft bei der Verwaltung der Elektrizität. Er tut dies auf sichere Weise und ohne Energieverschwendung. Wenn du Elektronik herstellst oder verwendest, ist es gut, etwas über dieses sehr gute Material zu erfahren. In diesem Artikel erfahren Sie, was ein nanokristalliner Kern ist. Sie werden herausfinden, warum er so gut funktioniert. Wir zeigen Ihnen, wie Sie damit Dinge herstellen können, die kleiner und stärker sind und mehr Energie sparen. Die Lektüre dieses Artikels wird Ihnen helfen, das nächste große Ding in der Leistungselektronik zu erkennen.

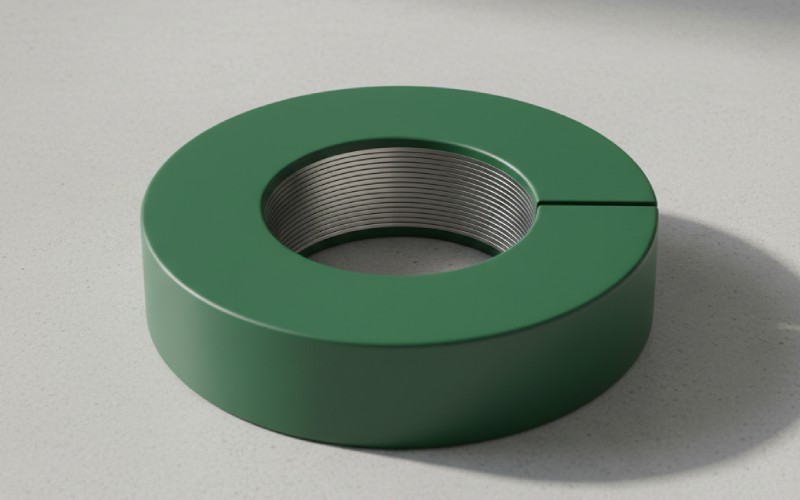

Ein nanokristalliner Kern ist eine Art Magnetkern. Er wird in Teilen wie einem Transformator oder einer Induktionsspule eingesetzt. Sie können sich einen Kern als den mittleren Teil dieser Teile vorstellen. Er sagt dem Magnetfeld, wohin es gehen soll. Diese Führung des magnetischen Flusses ist eine sehr wichtige Sache. Der nanokristalline Kern ist aus einem weichmagnetischen Material hergestellt, das nicht wie andere ist. Dieses Material hat einen ganz besonderen Aufbau im Inneren. Es besteht aus extrem kleinen Kristallen. Diese werden auch Körner genannt.

Diese Körner sind super, super klein. Jedes Korn ist weniger als 100 Nanometer groß. Dieser winzige Kornaufbau ist sehr wichtig. Sie verleiht dem nanokristallinen Kern seine sehr guten Eigenschaften. Er ist nicht wie andere Kernmaterialien. Dieser spezielle Aufbau macht den Kern sehr gut für seine Aufgabe. Sie hilft dem Kern, Energie fast ohne Abfall zu verwalten. Die Gesamtleistung eines jeden Bauteils, das diesen Kern verwendet, ist viel besser. Ein gut funktionierender Kern wird für neue Elektronik benötigt.

Das Verfahren zur Herstellung eines nanokristallinen Kerns ist sehr unterschiedlich. Am Anfang steht ein geschmolzenes Metallgemisch, eine so genannte Legierung. Diese Legierung besteht oft aus Eisen. Ihr werden andere Stoffe zugesetzt. Häufig werden Silizium und Bor hinzugefügt. Dieses heiße, flüssige Metall wird schnell abgekühlt. Es wird auf ein Rad gelegt, das sich dreht. So entsteht ein sehr dünnes Metallband. Zu diesem Zeitpunkt ist das Material amorph. Das bedeutet, dass es im Inneren keine Kristallform hat.

Der nächste Schritt im Herstellungsprozess ist der entscheidende. Das Metallband wird erneut sehr vorsichtig erhitzt. Dieser Erhitzungsschritt wird als Glühen bezeichnet. Dieser Vorgang lässt winzige Körner im Material wachsen. Die verantwortliche Person kann kontrollieren, wie groß diese Körner werden. So entsteht die endgültige nanokristalline Form. Durch diese sorgfältige Arbeit entsteht ein nanokristalliner Kern mit hervorragenden magnetischen Eigenschaften. Die gute Qualität dieses Kerns ergibt sich daraus, dass dieser Schritt auf die richtige Weise durchgeführt wird.

Die geringe Korngröße ist der Hauptgrund für die große Leistungsfähigkeit eines nanokristallinen Kerns. In einem magnetischen Material können die Wände zwischen den Körnern die Bewegung des magnetischen Flusses erschweren. Wenn die Körner sehr klein sind, gibt es viele von ihnen. Aber die winzige Korngröße dieses Materials macht es dem Magnetfeld leicht, sich zu drehen. Dadurch erhält der nanokristalline Kern eine sehr hohe Permeabilität.

Eine hohe Permeabilität bedeutet, dass das Material ein sehr starkes Magnetfeld halten kann. Dies ist eine sehr gute Eigenschaft für einen Magnetkern. Der magnetische Fluss bewegt sich sehr leicht. Aus diesem Grund verschwendet der Kern fast keine Energie. Ein kleines Korn hilft, den Energieverlust zu verringern. Das Innere des nanokristallinen Kerns ist so beschaffen, dass es die bestmögliche Korngröße aufweist. Dies trägt dazu bei, dass das elektronische Bauteil viel besser funktioniert.

Nanokristalline Kerne haben viele Vorteile. Sie haben eine Reihe von Merkmalen, die bei anderen Kernmaterialien nicht leicht zu finden sind. Wer nach Hochleistungsteilen sucht, wird feststellen, dass dieser Kern eine sehr gute Wahl ist.

Hier sind einige der wichtigsten Vorteile von nanokristallinen Kernen:

Diese Vorteile von Nanokristallin machen diesen Kern zur ersten Wahl für anspruchsvolle Anwendungen in der Leistungselektronik.

Der Energieverlust in einem Magnetkern ist ein ernstes Problem. Das Magnetfeld im Inneren des Kerns dreht sich sehr schnell hin und her. Dabei geht ein Teil der Energie als Wärme verloren. Dies wird als Kernverlust bezeichnet. Diese verlorene Energie führt dazu, dass das Gerät weniger gut funktioniert. Außerdem kann das Bauteil dadurch sehr warm werden. Um dies zu verhindern, wird ein nanokristalliner Kern hergestellt.

Ein nanokristalliner Kern hat aufgrund seines speziellen Kornaufbaus sehr geringe Verluste. Die kleinen Körner und das Material, aus dem er besteht, machen es den magnetischen Teilen leicht, sich zu bewegen. Das bedeutet, dass weniger Reibung auftritt und weniger Energie verloren geht. Die Verwendung eines nanokristallinen Kerns kann den Energieverlust erheblich verringern. Dies geschieht in einem Transformator oder einer Induktionsspule. Dies trägt dazu bei, dass das Produkt insgesamt besser funktioniert. Das Endprodukt wird dadurch besser und vertrauenswürdiger. Dieser geringere Verlust ist ein sehr großer Pluspunkt.

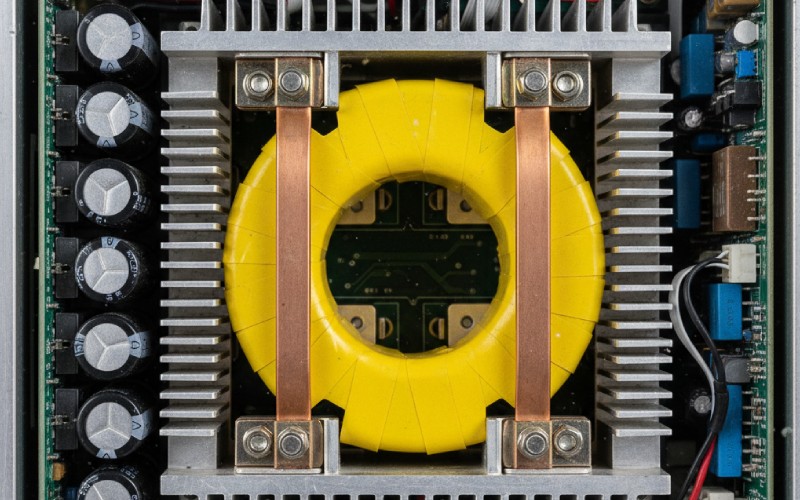

Die Verwendung eines nanokristallinen Kerns nimmt ständig zu. Aufgrund seiner einzigartigen magnetischen Eigenschaften eignet er sich hervorragend für alle Anwendungen, die eine gute Leistung und eine geringe Größe erfordern. Dieser Kern wird häufig in Hochfrequenzgeräten verwendet. Hier leistet er seine beste Arbeit. Eine großartige Anwendung für einen nanokristallinen Kern sind neuartige Stromversorgungen.

Andere Orte, an denen Sie einen nanokristallinen Kern finden können, sind:

Jede Anwendung, bei der gute Leistung und Energieeinsparungen erforderlich sind, ist ein guter Platz für diesen fortschrittlichen Kern. Seine Verwendung wird sicherlich noch zunehmen.

Ja, ein nanokristalliner Kern eignet sich hervorragend für hochfrequente Stromanwendungen. Das ist in der Tat einer seiner größten Pluspunkte. Viele neue Leistungselektronikgeräte arbeiten mit sehr hohen Frequenzen. In diesem Fall können die Hersteller die Bauteile viel kleiner und leichter bauen. Aber bei hohen Frequenzen haben viele normale Kernmaterialien einen sehr hohen Energieverlust.

Bei dem nanokristallinen Kernmaterial ist das nicht der Fall. Sein sehr geringer Kernverlust bleibt auch bei höheren Frequenzen niedrig. Das bedeutet, dass es bei Hochfrequenzanwendungen hohe Leistungen ohne Verluste aufnehmen kann. Dank dieser Eigenschaft kann ein Hersteller kleinere und leichtere Netzteile entwerfen, ohne die Leistung zu verschlechtern. Diese Fähigkeit wird für die Zukunft der Elektronik benötigt. Ein nanokristalliner Kern trägt dazu bei, den Umgang mit hochfrequentem Strom zu verbessern.

Wenn Sie sich für einen Magnetkern entscheiden müssen, ist es sinnvoll, die verschiedenen Arten zu vergleichen. Ein nanokristalliner Kern ist oft die beste Wahl. Das gilt besonders für Hochfrequenzanwendungen. Vergleichen wir ihn mit zwei anderen gängigen Kernmaterialien: Ferrit und amorphes Eisen.

| Eigentum | Nanokristalliner Kern | Ferritkern | Amorpher Eisenkern |

|---|---|---|---|

| Magnetische Permeabilität | Sehr hoch | Niedrig bis mittel | Hoch |

| Sättigungsflussdichte | Hoch (etwa 1,2 T) | Niedrig (etwa 0,5 T) | Hoch (etwa 1,5 T) |

| Kernverlust bei hoher Frequenz | Sehr niedrig | Niedrig | Mittel |

| Betriebstemperatur | Hoch | Mittel | Niedrig |

Sie sehen, dass der nanokristalline Kern eine hervorragende Mischung aus hoher Permeabilität und hoher Sättigungsflussdichte bietet. Er hat auch einen sehr geringen Verlust. Ferritkerne haben eine geringere Flussdichte. Das bedeutet, dass der Kern größer sein muss, um die gleiche Leistung zu erzielen. Amorphe Kerne haben einen höheren Verlust bei hohen Frequenzen. Der nanokristalline Kern ist für viele Projekte die bessere Wahl. Dieser Vergleich zeigt, warum er immer häufiger eingesetzt wird.

Die Wahl des richtigen Kerns ist ein sehr wichtiger Schritt. Ein nanokristalliner Kern hat viele gute Seiten. Aber es gibt ein paar Dinge zu bedenken. Erstens kann der Preis des nanokristallinen Kernmaterials höher sein als bei älteren Materialien wie Eisen oder Ferrit. Sie müssen entscheiden, ob die bessere Leistung die Kosten für Ihre Anwendung wert ist.

Zweitens ist das nanokristalline Kernmaterial ein dünner Streifen. Dieser Streifen kann leicht brechen. Das bedeutet, dass man ihn vorsichtig handhaben muss, damit er nicht bricht. Der Kern wird in der Regel aufgewickelt und in einer sicheren Hülle verkauft, aber Sie müssen trotzdem vorsichtig mit ihm umgehen. Schließlich gibt es eine Begrenzung der Formen und Größen, die Sie bekommen können. Sie müssen prüfen, ob Sie einen nanokristallinen Kern erhalten können, der für Ihre Projektanforderungen geeignet ist. Wenn Sie diese Dinge bedenken, können Sie die beste Wahl für Ihren Transformator oder Ihre Induktivität treffen. Davon hängen die gute Qualität und die Genauigkeit Ihres Produkts ab.

Die Welt der Elektronik ist in ständigem Wandel begriffen. Die Geräte werden immer kleiner und stärker. Außerdem müssen sie weniger Energie verbrauchen. Der nanokristalline Kern ist ein wichtiger Bestandteil dieses neuen Weges. Er hilft den Herstellern, diese schwierigen Ziele zu erreichen. Ein Transformator, der mit einem nanokristallinen Kern hergestellt wurde, funktioniert viel besser als ein Transformator mit einem alten Kerntyp. Diese bessere Arbeitsweise spart Energie.

Diese Energieeinsparung ist eine gute Sache für uns alle. Es bedeutet, dass unsere Geräte länger mit einer Batterie betrieben werden können. Es bedeutet auch, dass weniger Energie aus dem Hauptnetz verschwendet wird. Wir verwenden mehr Leistungselektronik für Dinge wie Elektroautos und saubere Energie. Diese gute Arbeitsweise ist also sehr wichtig. Der nanokristalline Kern bietet ein Leistungsniveau, das in der Vergangenheit nicht möglich war. Er hilft uns, die Zukunft intelligenter zu gestalten und weniger Energie zu verschwenden. Die allgemeine Veränderung, die dieses Material der Elektronik bringt, wird sehr groß sein. Die Genauigkeit der Energieübertragung ist ebenfalls eine Schlüsseleigenschaft, die dieser Kern bietet.